The business world is full of buzzwords. One that is gaining traction as companies strive to be better citizens is the concept of a Circular Economy (CE). CHEP is talking about it. Major pallet users are mentioning it in corporate sustainability and environmental goals. What does this concept have to do with the typical pallet company?

Let’s explore how even small pallet providers can get in on the act and turn this issue into a positive for their business. We have to start with defining the terms.

What Is the Circular Economy?

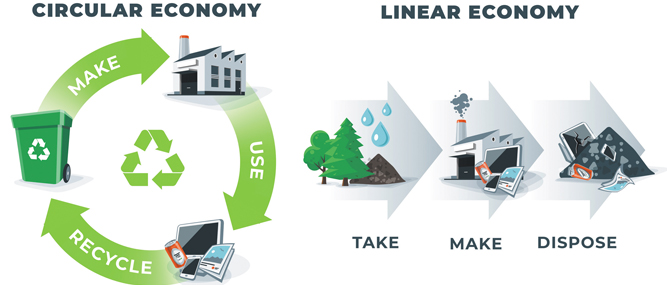

Circular Economy (CE) is defined by the Hellen McArthur foundation as the” process of eliminating waste and pollution, keeping products and materials in use, and regenerating natural systems.” Figure 1 shows the connections and relationships between the biological and technological cycles in CE.

Circular economy is a relatively new business concept that aims to extend the life of value-added products after they have completed their life cycle. The option of disposal after they have met customer or life cycle expectations cannot be the only option. Renting or leasing of goods is a business model that is closely related to CE: rental cars, residential, office, and storage space; construction and agricultural equipment; computers, phones, printers, furniture, access road matts, and pallets are some of the most common examples where goods are rented, used, returned, inspected and serviced before putting them back in the market.

A key aim in CE is to eliminate, decrease or mitigate pollution stemming from human activities like manufacturing, transportation, and building dwelling. Green-house gases (GHG) emissions are considered one of the most critical threats to climate change. Dioxide carbon and methane are the two most significant GHG produced by human activities and the industry and society should be committed to design and implement efforts to mitigate the impact of these GHG. There is a clear tendency in society to support efforts to decrease or mitigate the impacts of pollutants such as GHG. An increased number of consumers are becoming aware of the impact of human activities in the natural world and in humans’ own health. This increasing niche market demands services or goods that pollute less during their life cycles.

For CE to be successful, it needs to generate a positive economic impact. Otherwise, CE will not be sustainable in the long term. Profit organizations must make sure their operations produce a positive cash flow. Any effort to implement CE principles must align with core strategic values so the organization is sustainable in the long-term not just from the environmental and social point of views but also from the economic angle.

Product design is one of the critical activities in circular economy as 90% of the environmental carbon footprint and product cost is determined in this stage of the life cycle of product. Functionality, materials, manufacturing processes, packaging and end-of-life treatments are all determined during the product design stage. Once a product is designed, little is modified in the following stages of its life cycle.

Circular Economy and Wood Products

Wood is a renewable material that comes from trees and trees sequester and store carbon during their life spans. Carbon sequestration is a critical activity to mitigate pollution, and it can be achieved in different ways, but scientific work points out that growing and utilizing trees is one of the most efficient mechanisms to sequester carbon polluting the atmosphere. It has only been recently that wood and forest products’ companies have started to implement this powerful concept in their core business strategies. Now, they are seeking a way to gain or increase market access and increase competitiveness through touting their sustainability benefits. However, illegal harvesting and unsustainable forestry practices in certain regions of the world continue to overshadow the true and positive implications of sustainable wood utilization practices.

Wood and forest products’ industries already have a huge environmental advantage compared to other materials like concrete, metal and plastic. The fact that CE principles are currently applied to many wood products adds even more economic, environmental and social benefits to industries in this business sector. Some examples of current forest and wood products’ industries applying CE examples are:

• Reclaimed wood

• Access timber matts and pooled pallets

• Recycled pallets

Reclaimed wood is a growing sector in the United States as people try to repurpose old wood for new uses. These reclaimed wood businesses recover timber, lumber, flooring, doors and windows from old buildings to be sold as raw materials or novelty products. Reclaimed wood has become an important business activity given the perceived value of reclaimed wood products by some niche markets. However, some construction materials such as structural and non-structural panels and structural lumber have little or no value in many cases.

There are a number of circular models at play in the industry now. For example, timber matts or board roads rely on a renting and sharing business model where the renter is responsible for the assets as well as return. Pooled pallets have a very similar rental business model to road matts although typically some other person in the supply chain is responsible for return. A pooled pallet has an estimated life span of ten years, and currently there are well over 500 million pooled pallets embedded in the global supply chain. Because of improvements in the design of the pooled pallet, repairs are rarely required compared to non-standardized, whitewood pallets, making it easy for the pooled pallet owner to insert them back into the supply chain.

Recycled pallets are mostly made of used materials that come from other pallets. New fasteners, labor and energy are added, along with the used lumber to create a product that has the same functionality as a new pallet, but it is more affordable. Lumber from the old pallet that cannot be used anymore could be turned into energy or compost material, which is returned to the biosphere. As we can see from this example, a recycled pallet meets the three principles of circular economy: waste elimination, keeping products in the economy, and helping to regenerate natural systems.

Impact of CE Principles in the Wood Pallet Industry

Recycled, pooled and new pallet manufacturers might not be fully aware of the benefits that CE principles might be having in their business models. The application of CE principles requires a business model that works well for the investors, the customers and suppliers. Here you have four different strategies to take advantage of CE principles in the wood pallet industry:

Business strategy and market share increase: Recyclers and pooled pallet companies do not openly share their business models and how they operate with the general public. The application of CE principles to these two types of businesses can be used as a successful marketing strategy to attract potential customers who are interested in mitigating pollution and climate change. Green marketing strategies have increased over the last 25 years, and there are a large variety of for-profit organizations that highlight their efforts and application of CE principles to increase market share.

Innovations and carbon footprint reduction: New wooden pallets (made of 100% new wood) have a clear disadvantage compared to recycled or pooled pallets in regard to their environmental impact. Estimation of the environmental impacts of recycled and pooled pallets are allocated usually on the number of trips that the pallets perform before disposal. For example, the Pallet Foundation and the National Wooden Pallet and Container Association (NWPCA) developed an environmental product declaration (EPD) for wooden pallets. In this EPD the assumption for trips was between 10 and 66 trips depending on the type of pallet construction. In this EPD, pallets are only repaired once and after that they are disposed. There are several studies that look into the environmental impact of new wooden pallets, recycled and pooled pallets. These studies have different assumptions, but the overall agreement is that recycled and pooled pallets perform much better in regard to their environmental impact.

Manufacturing improvements and cost reductions: Recycled pallet manufacturers do more with less. The low prices these manufacturers paid for a used wooden pallet has a critical impact in the remanufacturing process cost. Lumber recycling gives the pallet manufacturers a change to minimize the utilization of new lumber when remanufacturing a pallet. In addition, many pallet recyclers have adopted lean thinking principles to their manufacturing processes increasing labor, space, energy, and other materials utilization. The cost reductions allow pallet recyclers and pooled pallet companies to offer customers a very competitive product in regard to cost, quality and delivery time.

Collaborations with suppliers, customers, and others: CE principles can also have a positive impact on the relationships with wooden pallet suppliers. Pallet recyclers need to develop an extensive network of suppliers of used wooden pallets for them to properly operate. In many cases, pallet recyclers sign long-term agreements to handle and collect used wooden pallets from supermarkets, warehouses and other distributors. Suppliers see this relation as a win situation for them because the pallet recycler eliminates the problems of having to dispose of wooden pallets. See accompanying table top rate your CE profile.

Working Toward a More Sustainable Future

Using goods that are designed and manufactured based on CE principles is critical for the future of our society. Consumers today are more aware and sensitive to environmental issues than a few years ago. But the wood products’ industry in general is still failing to properly communicate the benefits of using renewable materials and applying CE principles to their products and processes. Products such as boards, road matts, reclaimed wood, and recycled and pooled pallets are great examples where CE principles as applied as part of their business model. These industries could be used as successful examples in the application of CE principles for other wood products’ industries and beyond.

How to evaluate the implementation of CE principles in your company?

The following table presents a set of criteria that your company can use to rate or determine your CE profile. Use the following scale to rate each answer:

1. Strongly disagree 2. Disagree 3. Not sure 4. Agree 5. Strongly Agree

The following ratings will help to understand how well your company is doing toward the implementation of CE principles.

CE rating: More than 80. Your company is a CE champion

Between 50 and 80. Great progress toward CE

Between 25 and 50. Company is still lagging behind in CE principles

Less than 25. Company is not pursuing a CE strategy

_____ 1. Business strategy and market share increase

_____ 1.1. Life cycle assessment techniques can be used to determine the environmental impact of products and process

_____ 1.2. We market our products as environmentally friendly

_____ 1.3. The company is committed to reduce waste from the manufacturing operation

_____ 1.4. We have actions to mitigate the environmental impact of our operations

_____ 2. Innovations and carbon footprint reduction

_____ 2.1. My company has developed an environmental product declaration for at least one my products

_____ 2.2. Our products are designed using specialized software to optimize cost and performance

_____ 2.3. Our pallets are designed following CE principles: renewable materials/recycled, energy efficient, and options for end-of-life (reuse, recycle, remanufacture or disposal methods)

_____ 2.4. We have a continuous improvement team in our organization

_____ 2.5. We conduct audits of our manufacturing processes to detect opportunities for continuous improvement

_____ 2.6. Our employees have received training on lean thinking, six sigma or similar continuous improvement methodologies

_____ 3. Manufacturing improvements and cost reductions

_____ 3.1. In our company we track the use of raw materials

_____ 3.2. The waste in our company is properly classified as waste or recycled material

_____ 3.3. In our company we used cost allocation techniques to track the consumption of labor and raw materials by product or order

_____ 3.4. We use part of our waste as an energy source

_____ 3.5. We have a system in place to track the consumption of energy and water in our production facility

_____ 4. Collaborations with suppliers, customers, and others

_____ 4.1. We have developed partnerships with suppliers of used pallets

_____ 4.2. Our customers are aware of the carbon footprint of our pallets

_____ 4.3. We partner with industry associations, universities, or state agencies to improve the environmental performance or our products and processes

_____ 4.4. I collaborate with my customers to improve the environmental performance of my product

_____ 4.5. We partner with third-party logistics providers to track the environmental impact of our deliveries