DUNDEE, Ohio – Strategically located between several major markets in Ohio and surrounding states, Winesburg Hardwood & Pallet has become a highly successful business as a supplier of quality wood pallets and value-added products such as fine furniture and solid wood flooring. The family-run operation is widely respected for its deep community roots and caring initiatives such as the Winesburg Cares Fund, not to mention its state-of-the-art Dundee facilities. The company also recently has announced that it will build a new 80,000 square foot expansion.

Winesburg’s pallet product mix includes a range of new wood pallets produced on its recently purchased Woodpecker, as well as shipping crates. The company delivers to major Ohio markets, stretching as far west as Toledo Ohio, east as far as Pittsburgh, Pennsylvania, and as far south as Parkersburg, West Virginia.

A critical focus of pallet sales is on providing consistently accurate information on lead times to customers and delivering consistent quality. “With larger customers, our pallets are going into a palletizer or other system at the end of the line where boxes are rolling off,” said Kyle Schlabach, director of sales and marketing for Winesburg Hardwood. He noted that if pallets don’t arrive on time, the result could be a costly production stoppage. “We really hang our hat on giving accurate information on lead time and consistently hitting that delivery, time after time.”

Fire Aftermath – People from the Community Flocked to Help

Levi and Robert Coblentz started Winesburg Hardwood in 1975 as a logging operation, followed by establishing its first sawmill in 1977 and pallet production in 1978. In 2001, the company began its furniture business. Today, operated by a third generation of the Coblentz family, the company encompasses logging and sawmilling as well as pallet production (Winesburg Pallet), fine furniture (Palettes by Winesburg), and solid wood flooring (wood street creations).

The company has made a remarkable recovery from a fire that ripped through its previous sawmill. On the evening of July 18, 2017, a logging truck driver smelled smoke while making a late delivery. He discovered a smoldering sawdust bin and quickly called 9-1-1, but the fire spread rapidly through the existing structure. The mill was a total loss, including the lumber remanufacturing operations to make pallet components and the pallet manufacturing operations.

“The company rebounded from the fire,” commented Robert Coblentz, the second-generation head of the company that has transitioned to leadership by his sons, including Bryan Coblentz, company president. “We didn’t miss one shipment when we burnt down,” Robert stated. “People from the community flocked in to help.”

Part of that help came from other local companies contracted to provide sawmilling and other services. No workers were laid off in the wake of the fire. Some of them worked at the other mill in the interim, and others shifted into the company’s furniture and flooring operations. Mechanically inclined team members participated in building the infrastructure of the new mill. The new 25,000 square foot steel structure was completed and back in production by April 2018.

Selecting Equipment for the New Mill

A critical piece of equipment for the new mill was the purchase of a Cleereman 62-inch Lumber Pro head rig. Before the fire, they had run a Cleereman carriage and circular saw head rig and 54-inch McDonough band resaw, so Coblentz was familiar with the Cleereman line. Within a week of the fire, Robert worked with Cleereman to explore a replacement. After visiting sites running conventional head rigs and the Lumber Pro, company management visited the Cleereman offices in Wisconsin to seal the deal.

Unlike a conventional head saw, the log carriage is stationary, and the band mill is propelled on tracks. It also runs a double-cut blade and saws the logs in both directions, going and coming. The Lumber Pro is optimized with Paw Taw John controls, which utilize Joe Scan 3D scanners.

The Cleereman Lumber Pro thin kerf system is set up on a 17-degree slant, allowing slabs and sideboards to easily onto the conveyor.

Because the Lumber Pro cuts in both directions, the saw spends more time “in the cut” versus a conventional head rig, allowing for greater productivity. Another plus was the compact footprint of the Cleereman, noted Merl Coblentz, director of operations for Winesburg Hardwood.

The company purchased an MDI surround system metal detector and a new Nicholson R2 ring debarker with a proprietary 2-speed option from Cleereman Industries. Merl Coblentz observed that the company appreciates the design of the R2, which minimizes the loss of grade material. “It adapts to the size of the log very quickly and removes a lot less material,” he said. “Obviously, the outer part of the log is the best part.”

Merl commented about the decision to go with the MDI surround system, he said, “The benefits we are realizing are increased recovery, less down time and less damage to downstream machines. There is minimal maintenance required with our MDI system. I would recommend this system to anyone looking to detect foreign objects in wood.”

Other equipment selections included a Brewer cut-up line, a Morgan in-line notcher that has been upgraded in-house, and an AIT board stacker supplied by Pallet Machinery Group. Winesburg appreciates the value the stacker brings regarding boosting capacity, reducing labor requirements, machinery quality, and ease of operation. The company utilizes a Kiln-Direct heat-treat system for its HT pallets.

The result is a whole life cycle company that utilizes grade material for its furniture and flooring production while using the industrial material for pallets. The company has ready outlets for chips and sawdust, including farms and paper mills. It also uses some fiber internally to heat the boiler for its dry kiln.

Woodpecker Provides Production Boost and Reliability with Low Maintenance

Winesburg’s most recent machinery acquisitions include a Woodpecker pallet nailing system and a heavy-duty Brewer double arbor gang saw, which enables a significant capacity boost. While the old gang saw topped out at 20,000 to 30,000 board feet, the new Brewer will allow them to run as much as 40,000 to 50,000 board feet per shift.

As for the Woodpecker, Winesburg found itself looking to increase nailing capacity and manufacturing quality over the past few years. Previously, they had always gone with bulk nail machines, but the management team kept on hearing good things about Woodpecker from other pallet businesses in the vicinity.

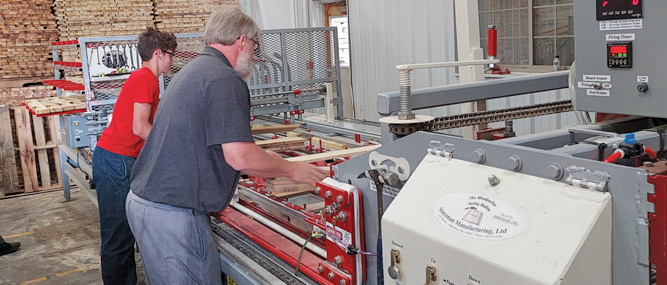

The Winesburg team took the time to see Woodpeckers in action at other facilities and visit Bert Stutzman and his team at Stutzman Manufacturing, the producer of Woodpecker and Woodpecker Junior nailing machines. Del Wagner, a partner at Midwest Machinery & Automation, the company providing sales and marketing for the Woodpecker line, stated that visitors are often pleasantly surprised by the level of sophistication on display. The Winesburg Pallet visit was no exception.

Midwest’s other pallet industry-facing equipment lines include the Woodpecker Junior, a block nailing system, and the MASTer Recycler pallet nailing system. The block pallet nailer he feels will compete well in the marketplace due to its competitive price point and the fact that it requires only three operators.

As for the Woodpecker, Winesburg chose to go with a 60" L x 60" W model, which met its required size range. In action, the Woodpecker flipper turns over the partly-assembled pallet so the top deck can be nailed, and the finished pallet ahead of it is pushed automatically into the stacker. It has an automated stringer feeder that is enhanced with a slanted design.

According to Wayne Wagner, partner and vice president of sales for Midwest Machinery and Automation, Woodpeckers typically enjoy a production of more than 1,200 units per shift range with three operators, ranging up to 1,500 units. Key selling points are simplicity and durability. Wayne stressed that there are no complicated electronics or PLCs or time-consuming maintenance routines. They have built a reputation as durable, safe and inexpensive to maintain.

Looking back, Robert Coblentz was happy with the move to Woodpecker. Coblentz stated, “I have had other nailers in the past. And the Woodpecker is just crazy fast.”

He added, “Woodpecker nailers are easy to run… so simple anyone can run one,” he added, emphasizing that the Woodpecker’s switches are just easier than control panels.”

As of the time of our interview, Winesurg’s new Woodpecker had already produced over 130,000 pallets and counting.

Winesburg Cares Fund

A high value at Winesburg Hardwood & Pallet is taking care of its employees and the community. One way the company mobilizes assistance to the right place is its Winesburg Cares Fund. The genesis of this effort goes back several years when a Winesburg employee required help. Some employees started a fundraiser, and several more employees contributed. The success of that first venture planted the seed to establishing the Winesburg Cares Fund. “Our community is very family-oriented,” Schlabach explained. “People are always looking out for each other.”

Today, the Winesburg Cares Fund lives on, serving charitable and educational purposes, based on need, to past, current, and future employees and their families, as well as to members of the Winesburg, Ohio community who experience emergency hardship. Some employees contribute through regular payroll deduction. Others donate through participation in large spring and fall events, including entertainment, dinner and a charity auction. Employees run the initiative and serve on the Board. None of the Coblentz family sits on the Board.

In June 2021, the company announced that it would be undertaking an 80,000 square foot expansion in three phases, which would create an additional 50 jobs when completed. There are currently about 198 employees working in the furniture and flooring divisions and 42 in the sawmill and pallet group

From sustainable log harvesting to full log utilization, the company lives its official vision of “handcrafting the highest quality products on earth and leaving it a better place.” The Coblentz family tries to live out its mission of being “an innovative, integrity-driven, forest-to-final manufacturer.”

“It’s great to have the best quality built, efficient, and updated machinery, but truly our greatest asset is the people we employ, and the team that has come together to accomplish our goals,” concluded Bryan Coblentz.