In “price taker” markets, successful businesses are the low cost producers, and pallet manufacturers are no exception.

The single largest cost component of pallet manufacturing is raw material costs. Cants and lumber typically account for over 60% of operating costs. In the last three decades, cants have replaced lumber as the primary raw material for hardwood pallet manufacturers. As stumpage prices and competition for wood-based raw materials increase, pallet cant prices will continue to rise as well.

The value of cants to pallet manufacturers is a function of pallet part yield and sawing costs. A previous U.S. Forest Service study examined the percentage of unsound volume in hardwood pallet cants. This research showed that 90% of hardwood cants have less than 10% unsound volume, and that only 2% of cants have more than 30% unsound volume.

This study, as well as the others, supports the justification that cant quality can and should be assessed in order to predict pallet part yields and to better control raw material costs. Knowing the value of cants will help pallet manufacturers more accurately control costs and price products. Nevertheless, even though pallet cants are the largest volume hardwood lumber product produced in the U.S., no standard grading rules exist for pallet cants.

The National Hardwood Lumber Association (NHLA) provides grading criteria for Common Timbers and Industrial Blocking that indicate the allowance of unsound wood as long as strength for intended use is not impaired due to this defect. However, unsound volume restrictions and size and number of cutting units are not specified. Other hardwood cant grade rules have been developed over the years, but they have been complex and not reflective of pallet part acceptance criteria.

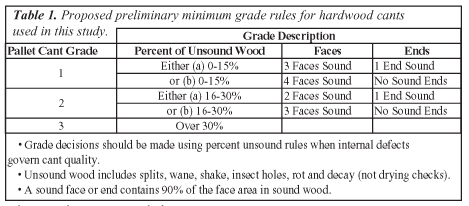

Virginia Tech researchers earlier developed cant grade rules representing a three-level partitioning of the range of cant quality observed during previous mill studies. Using these preliminary grade rules, researchers at Virginia Tech recently studied the relationship between cant quality and pallet part yields. As a result of this study a revised cant grading procedure was proposed.

Research Objectives

1. To determine the relationship between cant quality and the yield of pallet parts

2. To determine how processing systems and saw patterns affect pallet part yield.

3. To develop a practical pallet cant grading procedure.

Materials and Methods

Processing data was collected from 28 hardwood pallet mills located throughout the central and eastern U.S. The sampled mills utilized a range of processing equipment. Cant and pallet part characteristics also varied between mills.

Two bundles of about 2,000 board feet of cants were graded at each mill study location. Cant bundles were randomly chosen without regard to appearance. Cants were separated according to three preliminary hardwood pallet cant grades. These grades are described in Table 1.

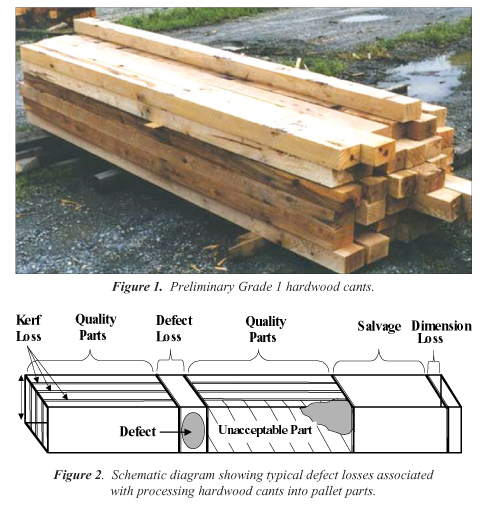

Hardwood cants were graded by determining both the presence and extent of internal or volumetric defects, such as heart rot, decay, wane, insect holes, shake, and splits. The cant grade was based on the percentage of unsound wood volume resulting from these defects. Cants receiving the preliminary grade of Grade 1 or Grade 2 were then further graded by examining the ends of the cants and all four faces. A cant end or face was determined to be sound if more than 90% of its surface area was sound. Final cant grades were assigned according to face grades. Cants were separated and restacked by grade, and the cant volume per grade was calculated and recorded. Figure 1 shows typical hardwood pallet cants from Grade 1.

Each graded stack of cants was sawn into pallet parts separately. In all studies, cants were first cut to appropriate lengths using a single-blade trim saw. The cants were then ripped into final part thicknesses. Ripsaws studied during data collection were of two basic machinery classifications: circle gang saws and multiple band saws. For each mill study, the type of sawing blade used and its corresponding saw kerf were recorded. Saw kerf was determined by measuring the width of the saw teeth at the cutting edge to the nearest 0.001-inch. Figure 2 shows a schematic diagram of typical defect losses associated with processing hardwood cants into pallet parts.

As cants from each grade were processed separately through the ripsaws, unusable parts were discarded, and the remaining parts were sorted and stacked by size. While each mill discarded parts with serious defects, the criteria by which parts were discarded varied between mills. Parts accepted by saw operators were evaluated for conformance to industry standards (Uniform Standards for Wood Pallets). Parts graded below the “limited use” category and that did not conform to the nailing area requirements in the standards were also rejected. All acceptable parts were tabulated according to part size classifications.

Results and Discussion

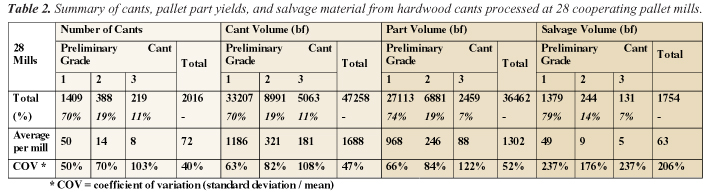

The data collected at each mill included number of cants, cant volumes, part volumes, salvage volumes, and ripsaw kerfs. Table 2 summarizes the yield study results for the 28 mills studied. In all, 2,016 hardwood cants totaling 47,258 board feet were graded during these studies. The total volume of pallet parts and salvage material produced were 36,462 and 1,754 board feet, respectively.

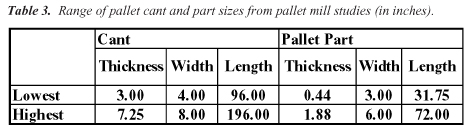

Table 3 contains the range of pallet cant and part sizes from the pallet mill studies. The ranges represent the typical cant and part sizes sawn by the pallet industry.

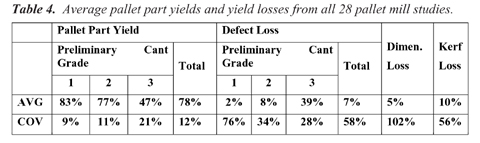

Table 4 provides a summary of pallet part yields as a function of cant grade, defect loss, dimension loss and kerf loss. Average total part yield was 78% for all mills studied, and cant Grades 1, 2, and 3 yielded an average of 83%, 77%, and 47% part volumes, respectively. Part yield COV (coefficient of variation, or standard deviation/mean) was 9%, 11% and 21% for Grades 1, 2, and 3, respectfully. Not surprisingly, yield COV for Grade 3 cants was relatively large since Grade 3 simply represents all levels of unsound wood greater than 30%.

Hardwood Cant Quality Distribution

The relative number of cants per grade indicates the quality distribution of cants used by the mills studied. Table 2 contains the total volume of each cant grade sawn at the study pallet mills. Of the 2,016 cants graded in the study, 70% (1,409 cants) were Grade 1, 19% (388 cants) were Grade 2, and 11% (219 cants) were Grade 3.

The high percentage of Grade 1 cants by volume supports the basis that the pallet industry is sawing a high percentage of sound cants. Nevertheless, the results of this study are only applicable within the parameter ranges of the pallet mills sampled. Market forces may result in changes in these distributions.

Yield Losses

Three yield loss components were calculated: defect loss, dimension loss and kerf loss. From Table 4, average yield loss (by component) for all cants processed was as follows: 10% kerf loss, 7% defect loss and 5% dimension loss.

Defect loss was determined for each cant grade. Kerf and dimension losses are a function of the cutting bill, ripsaw blade orientation, equipment, and pallet part and cant geometry. They are not affected by cant grade and were therefore determined for all cants as a whole. Pallet part yield is a combination of both pallet stringers and deck boards.

Average defect losses were 2%, 8% and 39% for cant Grades 1, 2, and 3, respectively. Defect loss COV for Grades 1, 2, and 3 was 76%, 34% and 28%, respectively. Although COV was larger for Grades 1 and 2, the low mean values reflect relatively small standard deviations and are consistent with accuracy in the grading rules.

Statistical analysis indicated that defect losses were significantly different between all grades. Defect losses were expected to be consistent with the percentage of unsound material by grade according to the proposed hardwood cant grading rules. The significantly low defect losses for Grades 1 and 2 were due to high quality cants with low volumes of unsound material.

In this study, dimension losses in pallet mills producing multiple part sizes were nearly 2% lower than mills producing only single size parts. Mills salvaging short cant sections reduced dimension losses by 0.8% compared to mills not salvaging cant sections.

Effects of Ripsaw

Selection on Yield

Ripsaw kerf ranged from 0.036-inches to 0.188-inches with the average being 0.109-inches. Ripsaw kerfs were compared between circle gang saws and multiple bandsaws. The average saw kerf thickness for multiple bandsaws and circle gang saws were 0.056-inch and 0.138-inch, respectively.

Thicker saw kerfs resulted in higher kerf losses and lower yields, which implies higher part costs. The average kerf loss from multiple bandsaws and circle gang saws was 6% and 13%, respectively. This difference in kerf loss reveals that a 7% increase in yield can be attained through the use of thin kerf multiple bandsaws.

The large variation in kerf loss within each saw kerf class is attributed to differences in sawing patterns associated with production of different pallet part sizes. However, statistical analysis did indicate that a significant correlation exists between saw kerf size and yield loss due to kerf.

Evaluation of Grading

Determining the magnitude of internal defects in a cant was subjective, but a good approximation was possible by examining both ends and all four sides. The grading process was quick because cants with unsound volume greater than 30% were assigned a final Grade 3 without requiring the application of face grading rules. Determining the total volume of unsound material often allowed the grader the ability to forgo further examination of the sides and ends.

One problem with the grading criteria used in this study was the caveat that a Grade 1 cant must have at least four faces that contain 90% or more of the surface area in sound wood. A cant containing wane (usually from small diameter logs) but an otherwise low volume of unsound wood (less than 15%) could be initially classified as a Grade 1 cant. However, the strict “90% sound wood face” grading criteria downgraded some Grade 1 cants with low percentages of unsound wood to a Grade 2. Grade 2 cants often contained high percentages of sound material. Resulting defect losses were lower than the expected 15%-30% for this grade.

The proposed face grading criteria was not accurate. The fact that average defect loss was lower than expected indicates the high percentage of sound wood volume in hardwood cants. Low defect losses, high average pallet part yield, and little variation within these two data groups support the adoption of a singe cant grading rule.

Current market prices for hardwood cants and pallet parts indicate that a minimum pallet part yield of roughly 2/3 is required for a typical pallet manufacturer to break even economically. Consequently, this indicates a maximum allowable yield loss of 33%.

Since this research shows that average kerf and dimension losses combine for 15% of total yield loss when processing hardwood cants into pallet parts, it appears that unsound defect losses in excess of 18% would cause cants to become unprofitable for pallet part production.

However, it is important to note that some unsound wood volume will be included in kerf and dimension losses during cant processing. It is also true that, depending on the grade of the part, significant amounts of unsound wood are permitted in pallet parts (Uniform Standards for Wood Pallets 2003). Other restrictions include no decay in stringer notch areas, and no wane or decay on the outer edge of end boards or on the exposed sides of stringers or blocks.

Based on the break even yield loss maximum of approximately 33% — which includes the 15% for kerf and dimension loss unrelated to cant quality or grade — it is reasonable to allow an additional 15%-18% unsound wood volume to be permitted present in cants to compensate for unsound wood lost in kerf and dimension losses and unsound wood permitted in pallet parts.

It is recommended that the hardwood cant grading rules used in this study be simplified into a single, practical grade rule based entirely on a maximum allowable unsound wood volume of 1/3 total cant volume (33%).

Recommendations

For Cant Grade Rules

Hardwood cants range from 4×6 inches to 8×8 inches in width and thickness and 8 feet and longer in length. In contrast to general lumber or boards, a cant has four distinct faces and two ends that require inspection when an attempt is made to determine its overall quality.

In the case of hardwood cants for pallet parts, quality is determined by the percentage of sound wood volume in a cant from which pallet parts can be manufactured at a profit. From this research, it has been determined that a cant should have at least 2/3 sound wood volume. Unsound wood present in the form of heart rot, decay, insect holes, splits, shake, and wane reduce cant quality and compromise the yield of pallet parts that can be obtained. Sound knots, however, are perfectly acceptable.

Because of the three dimensional similarities between a cant and a log, a simple cant grading technique is proposed that draws on log grading criteria used by the Forest Service Standard Grades for Hardwood Factory Lumber Logs. Hardwood cants come from the center of a log and are not significantly affected by sweep or crook that may be present in a log. No considerations for these defects are necessary. Since it has been shown that a reasonable economic indicator for allowable unsound wood in a cant is roughly 33%, the proposed hardwood cant grading rule allows up to, and including, 1/3 of the volume in a cant to consist of unsound wood. The following is a proposed grading procedure for hardwood pallet cants.

1. Observe and evaluate all four cant surfaces for volume-reducing defects such as heart rot, decay, insect holes, splits, shake and wane.

2. Based on the area of unsound wood defects, select the second from the worst face. This is then the grade face.

3. Evaluating the grade face, determine the percentage of unsound wood (GFD) as a ratio of the surface area of the unsound defects on the face (SAD) to the surface area of the face itself (SAF).

Grade face volume deduction (GFD) = SAD (in2)

SAF (in2)

4. Check for unsound end defects. Estimate interior unsound wood volume deductions present at the ends of the cant (CED) using the methods for interior deductions described in the Forest Service Standard Grades for Hardwood Factory Lumber Logs. If unsound wood visible on the end of a cant is adjacent to or the same as unsound wood observed on that end of the grade face, ignore that unsound defect in the grade face.

5. Add the grade face (GFD) and the percent of cant end (CED) volume deductions to determine the percent of total unsound wood volume present in the cant.

Total unsound wood deduction = GFD + CED

6. Cants with unsound wood volume in excess of 33% (1/3) are below grade, and therefore, cull material.

Conclusions

• Cant quality significantly affects pallet part yields. Preliminary cant Grades 1, 2, and 3 used in this study resulted in average pallet part yields of 83%, 77%, and 47%, respectively.

• The preliminary hardwood cant grades resulted in average defect losses of 2%, 8% and 39% for Grades 1, 2, and 3, respectively.

• The pallet industry is using a relatively large percentage of sound cants. Preliminary cant Grades 1 and 2 (cants with less than 30% unsound wood volume) represented 89% of the cants and cant volume in this study.

• Kerf loss is the largest yield loss component from processing pallet cants into parts. In this study, kerf loss was 10% followed by defect and dimension losses at 7% and 5%, respectively.

• Pallet part yields are 7% higher when thin-kerf bandsaws are used instead of circle gang ripsaws.

• Cutting multiple length parts resulted in a 2% higher yield compared to single length part production from cants. Salvaging short material increased part yield nearly 1%.

• A new hardwood pallet cant grading procedure was proposed based on the Forest Service Standard Grades for Hardwood Factory Lumber Logs. In this new procedure, unsound wood volume is tallied from both a specified grade face and the cant ends. When combined, unsound wood volume is limited to a maximum of 1/3 the surface area of the grade face and the unsound wood in the ends of the cant.

For more information, contact Peter Hamner at the Virginia Tech Center for Unit Load Design at (540) 231-3043 or e-mail phamner@vt.edu.

(Editor’s Note: Hal Mitchell is operations manager for Atlanta Hardwoods Corp. in Mableton, Ga.; Marshall White (professor emeritus and past director of the Virginia Tech Center for Unit Load Design) is president of White & Company Packaging Solutions Inc.; Phil Araman is a project leader with the U.S. Forest Service Southern Research Station; Peter Hamner is a research associate with the Virginia Tech Center for Unit Load Design.)