CHEP USA has unveiled a new collection of products and services with the tagline “This is the Supply Change™.” Theses services look beyond just pallets as the rental giant looks to take some of the products and services it has developed for its largest customers and make them available to others.

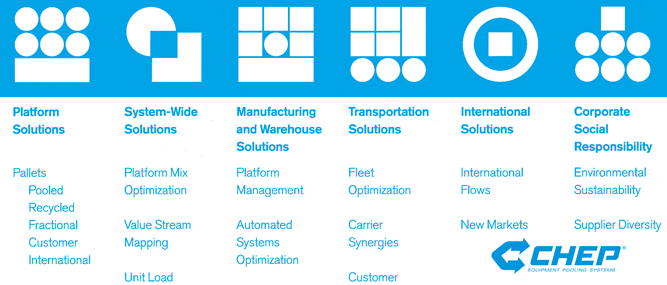

Called the Solutions Portfolio, this collection of services ranges from reducing product damage to minimizing empty trailer loads to creating a strong sustainability and environmental procurement program to human resources and supplier diversity initiatives. Some of the programs are offered on a fee basis. Others are value-added offerings that mutually benefit CHEP and its customers.

Todd Hoff, vice president of marketing for CHEP North America, explained, “We are actually the largest backhaul shipper in the United States. It is about using our network and sharing networks with our customers.” CHEP has worked with customers to buy fleet services from them, eliminating empty miles and reducing logistics costs for CHEP.

Brambles Ltd., the corporate parent of CHEP, owns a variety of software assets, such as Lean Logistics, that

can help optimize shipping lanes and reduce empty miles. The CHEP network has 45,000 unique shipping lanes and over 20,000 locations across North America.

Specifically, CHEP offers fleet optimization, carrier synergies and customer pickup options. According to CHEP, the company eliminated 1.28 million empty miles for customers last year using fleet optimization where it bought and sold excess capacity for customers. Hoff added that customers can earn direct revenue while CHEP gains capacity. And empty miles are eliminated along with CO2 emissions.

Carrier synergies exist where CHEP creates closed loops by combining matching lanes within its network. And customer pickup services allow users to receive a platform fee discount and maintain control of its delivery timetable.

A senior director of inbound logistics for Walmart Stores commented,” CHEP helped us save 856,000 empty miles and reduce 2.7 million pounds of CO2.”

Using its CHEP Innovation Center, which is a world-class testing lab and design facility, CHEP has offered services to optimize unit loads for years. Now that service is being formalized and made available to more than just the top-tier of its customer base.

Hoff stated, “We have worked with large retailers and product manufacturers over the years to develop some of these services for them. What we have not done is take these services and offer them in an organized way to some other large customers and small to medium-sized customers.”

In 4-6 weeks, CHEP can test your packaging to reduce cost and product damage. This includes impact, compression, vibration and environmental simulation tests. CHEP will help customers identify the best design configurations from individual product packaging to full unit load design. Also, this service offers a data driven approach that will help customers discover the true keys to cost savings and the important metrics to focus on for the future.

CHEP pointed out in its sales brochure that product damage costs manufacturers over $2 billion a year. CHEP has developed an extensive product damage database and value stream mapping tools to identify the best way to address these concerns for a wide variety of shippers.

For example, CHEP claims it helped a paper manufacturer save $500,000 and reduce product damage by 75%. A collaborative analysis project revealed that damage was caused by the clamp loader, which crushed 4% of the manufacturer’s product during handling. By switching to forklifted pallets, the paper company was able to substantially reduce product damage.

Three major grocery retailers using the unit load optimization solution reduced damage at their distribution centers and each saved about $300,000 throughout their supply chains.

And the last two focus areas are kind of far from pallets, but they aren’t really when you think about them. Pallets are a major part of the supply chain and can help drive the environmental performance of every aspect of the process. More than just rhetoric, CHEP can help customers develop strategies and measure success when it comes to reducing a company’s carbon footprint and sustainability scorecard. Some of the strategies employed include: cube optimization, racking square footage reduction, corrugate reduction and recycling, elimination of landfill waste, equipment runtime reduction, package materials reduction and much more.

CHEP boasted as part of its Better Planet initiative, that it assisted a major beverage company in filling 850,000 empty miles through backhaul improvements, which resulted in a net gain of $1.6 million in additional revenue.

Finally, CHEP has spent lots of time and effort on its supplier diversity program to ensure that minority-owned and women-owned businesses are given an opportunity to thrive and to contribute to the community. CHEP will help customers customize a program, measure its success and provide best practices insights from its network.

CHEP stated that due to its unique position across the entire supply chain, it has captured data and experience into solutions that encompass enterprise logistics, supply chain platforms, transportation, international trade, manufacturing, warehousing, harvesting, processing, distribution and store fulfillment, in addition to sustainability and supplier diversity.

So, let’s analyze what these moves by CHEP mean for the pallet industry. The white-wood sector needs to be on alert that data is going to become a bigger part of your business. And CHEP has a big head start in this area. The white-wood sector may be able to match or even exceed CHEP’s network in some respects. But when it comes to software and data management, the industry has some catching up to do. This will take a collaborative approach for companies and even competing regional players to work together.

The industry already has much of the unit load expertise needed to achieve packaging cost reduction. That is where companies should look at the Best Load software offered by White & Company (http://www.whiteandcompany.net/best-load.html).

Pallet companies by working with other pallet companies and coordinating backhaul opportunities can mimic some of these same lane reductions. This is where organizations like PALNET USA, the Pallet Alliance or 9BLOC can offer transportation savings. But collaboration is the key.

There is a growing collection of minority-owned or woman-owned pallet operations. Some large national brokers or pallet networks can take advantage of this to meet corporate responsibility goals in much the same way that CHEP has done. Although the Solutions Portfolio approach is a good idea, the execution is what matters most. And white-wood companies can be successful too if they sell themselves as more than just a pallet guy. If CHEP can succeed, it will find ways to get even more entrenched with customers. And CHEP may be able to charge for some of these services too as a way to make more revenue even as it gets tougher to move some clients from white-wood pallets to rental pallets. Why can’t the white-wood industry do the same thing?

Data and service will be a huge part of this initiative. Read more about pallet data in this month’s letter on page 10.

Focusing on solutions, data and reduction supply chain cost will certainly be an important part of the pallet conversation moving forward. The question you must consider is, “What is my response and what do I have to offer?”