PULASKI, Tennessee — Mike McComiskey’s pallet manufacturing company, JM Forest Products, is located in Tennessee, the heart of the hardwood lumber industry.

However, changing hardwood markets in recent years have required McComiskey — like some others in the industry — to adapt and transition most of his customers to pallets made of Southern Yellow Pine.

McComiskey knows a thing or two about machinery, and over the years he’s adapted and modified machinery and equipment, too. In fact, he tries to avoid buying brand new equipment if he can.

When it came time for JM Forest Products to get a new notching machine, though, he turned to a company with experience in the pallet industry, too: Go Fast Manufacturing.

Go Fast Makes Ideal Notcher for JM Forest Products

“I try like crazy not to buy new equipment,” McComiskey admitted.

However, he recently added a new, custom double-head notching machine designed and built by Wisconsin-based Go Fast. The new Go Fast notcher replaced two other notching machines, old equipment that McComiskey bought and refurbished; one was for stringers up to 65" long, and the other could notch material 32 to 132" long.

One machine’s chain feed system only fed the blank stringers as far as the notching heads and did not carry the board all the way through. As a result, chains broke several times a week, interrupting production.

McComiskey wanted one machine that could handle both short-length and long-length material and could achieve faster feed rates. The Go Fast notcher can take material from 30" up to 10 feet. “I liked the design,” he said, that Go Fast developed. “It pulled the board all the way through.”

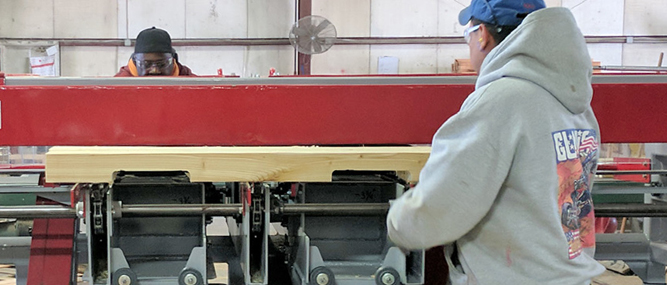

The notching machine is capable of cutting 4,000 stringers per hour, according to Go Fast. It features a three-strand chain infeed system that uses cogged conveyor chain to pull the material through the cutter heads. The machine is equipped with a 1.5 hp infeed motor and 20 hp cutter motors.

The old machine also required a lot of time to set up for notching material of a different length. It required an “act of Congress” to change, quipped McComiskey. With the Go Fast notcher, “Push a button, the cutter heads move.”

Go Fast pricing for the custom machine was very reasonable, indicated McComiskey. “You start looking for custom made — by golly, it just made sense.”

And McComiskey liked the fact that the owners of Go Fast also own a pallet business. “They understand what’s going on,” he said.

Go Fast also manufactures standard notching machines, a single-head model and a double-head model, and the company plans to introduce a new economy notching machine in the near future. The company’s product line also includes band resaws, lumber grade systems, end trimmers, chop saws, dedusters, stacking racks, and material handling equipment.

Go Fast offers multiple trimmers, a double endtrim (DET), multi-head endtrim (MET), and board trimmer (TS10). The standard DET-20 features two adjustable heads and can process up to 72" long material; longer options are available. It can trim lumber or cants and comes standard with 5 hp motors and 20" carbide blades. The MET can be configured up to six heads for a variety of applications. The TS10 model is designed for trimming boards and can cut up to 40 boards per minute.

Lumber Processing Operations

For SYP, McComiskey buys mainly 2x material in random length ranging from 2 feet to 20 feet. As prices of 2×4 have escalated, it is cheaper to buy 2×8 and 2×12 material and remanufacture it. For crates and containers, he also buys panels of oriented strand board and plywood. He obtains material from mills in Alabama, Mississippi, Georgia, Arkansas, North Carolina, and even Texas.

A building housing a board line for processing SYP is equipped with a number of machines. Material can be cut to length on a Pacific Trail package saw or a Newman Machine KM-16 multi-trim saw. Other machines for ripping or resawing include a Brewco rip saw and a sizer-splitter, a CMI rip saw, and a Baker double-head bandsaw. The company also has an assortment of chop saws for small jobs as well as specialty notchers and drilling machines that McComiskey developed.

The company buys a small volume of 4×6 and 4×8 hardwood cants in random length and also some 4/4 rough lumber. For processing cants, the company has a unscrambler that feeds the material line to a line of Pendu machines. A chop saw cuts the cants to length, and the blocks are fed in-line to a gangsaw to be cut into boards or stringers. The finished components are collected by a stacker.

Company Background & History

JM Forest Products is located in Pulaski, about 70-plus miles south of Nashville. It is about 5 miles west of the I-65 Corridor, which runs north and south.

The company has five buildings situated in a campus arrangement on 17 acres, a total of 60,000 square feet of space. It employs about 42 people, from management staff to truck drivers and entry-level workers. JM sends out four to six truckloads of finished goods daily.

McComiskey, 54, didn’t go looking for the pallet industry; in a manner of speaking, it came to him. He got into the business through his father in 1997. At the time McComiskey was a national installation manager for a sign manufacturing business, overseeing the design and installation of signage for Enterprise car rental company. He commuted 80 miles to work every day in Nashville.

He went to visit his father, who was living in Connecticut and was diagnosed with terminal cancer. His father had a business that manufactured wood crates and containers for a customer in Connecticut. McComiskey had one daughter at the time, less than a year old, and he wanted work that would allow him to cut out the lengthy commute every day.

He made a spur of the moment decision in Connecticut to launch his own business to begin making wood crates and containers back in Tennessee for his father’s customers. “I never quit a job without giving two weeks’ notice,” he said, but he called his employer to tell them he was giving them two hours’ notice.

McComiskey borrowed some money, bought some equipment from his father’s estate, and leased a 2,500-square-foot building to get started. A year or two later, he expanded the business into pallets and skids. “It’s taken off from there,” he said.

It would seem that McComiskey had a good background for the pallet industry. He worked as a machinist for an uncle coming out of high school, but after four years he decided he wanted to go to college. He continued to work full-time while attending Middle State Tennessee University part-time for eight years to earn a bachelor’s degree in business management. After graduating he worked as a maintenance technician for a vending machine company before becoming employed with the sign manufacturer.

He moved the business to the current location in 1999. He and an uncle constructed every building on the property.

Custom Manufacturing Gives JM Forest Products a Nice Niche

McComiskey still makes the same type of wood container he started the business with, but it’s for a different customer. In the pallet arena, the company specializes in custom, nonstandard pallets. For example, JM produces a 24×16 pallet for a customer every week. It also makes skids that are 20 feet long. “No GMAs,” said McComiskey. “You can have them.”

JM has the capability to design custom pallets for customers and uses pallet design and CAD computer programs. The company makes a lot of finished goods that require special notching, cutting, chamfering, or drilling. A lot of pallets or containers are assembled with bolts or screws.

JM once designed and built crates to ship airplane wings. They were 88 feet long by 13 feet wide and 6 feet tall. Loaded on a truck, the load was too wide to exit the company’s gate, and a post had to be removed and the gate widened.

McComiskey’s company has customers in the automotive industry, military, services, foundries and steel processing, food products, and corrugated sectors. Customers range from middle Tennessee, southern Kentucky, northern Alabama, and some in Mississippi and Georgia. “If it’s unique, value-added, freight becomes less of a factor,” noted McComiskey.

McComiskey transitioned customers to SYP because of the shortage of low-grade hardwood material. “You just can’t get enough,” he said. About 90% of the company’s pallet production used to be hardwood and 10% SYP; now it is 85% SYP and 15% hardwood.

With his machine shop background, over the years McComiskey has designed equipment and in some cases took an existing machine and modified or improved it. He gets a lot of enjoyment out of solving challenges related to machines and equipment, like making them faster or making the job easier. “That gives me more of a charge than anything,” he said.

Pallet Production

The company builds some standard type pallets, however. For assembling those, McComiskey has an assortment of nailing machines: a Rayco, a Gap, a Viking, and a Woodpecker. “We run them every day,” said McComiskey, “but we also built a lot of specialty stuff…That’s always been our focus.”

“We’re doing a lot of block pallets right now,” he added. For cutting blocks for block pallets the company has a Morgan block saw and automated pop-up saw.

About 20 workers are devoted to building pallets or containers manually with pneumatic nailing tools. The company uses DuoFast pneumatic nailing tools and collated fasteners. For the Viking 304 nailing machine, JM uses Magnum brand nails from Mid Continent Nail Corp.

Sharp Tool is the company’s supplier of circular saw blades, and Southeastern Metals for bandsaw blades. McComiskey uses cutting tools supplied by Profile Technology for the notching machine as well as some other machines.

McComiskey has no good markets for residual material. Some scrap wood is burned to heat the company’s buildings, and some is incinerated for disposal. Cant trim ends are given away for firewood.

JM does not offer pallet recycling services. If a customer wants recycled pallets, McComiskey buys them from another company that is operated by a fellow who has been a friend since childhood.

Good People Enable Business Growth

As the business grew and he added employees and supervisory staff, McComiskey has realized the importance of good employees. “What’s made us get to where we are is the people here,” he said. “I can’t hire better people than who I’ve got right now in my management and some of my supervisors.” For the first time, he said, he has a cohesive management team. “Everybody sees the same picture.”

Employees get all major holidays and a week of vacation the first year, then two weeks. The company sponsors a medical wellness program and safety program.

McComiskey provided group insurance until the Great Recession impacted his company in 2008; the business paid 90% of the insurance premiums for employees. “I told them it was not sustainable,” said McComiskey, after the onset of the recession and the drop-off in business. He gave employees a choice, either sharing the cost of the premiums 50-50, or employees could accept a raise and buy individual health insurance if they wanted it. They voted to take the raise.

Now that his workers are older, McComiskey wants to make their jobs easier but increase output. “We are really taking some hard looks at automation,” he said. “I see robots in the future.”

McComiskey and his wife have been married 25 years. One daughter now is a junior in high school, one is a senior in college. They are “A” students. McComiskey has coached teams for both daughters in soccer and softball and is still coaching the team for his youngest daughter. For vacations over the years, the family hit the road instead of the beach. “I wanted my kids to see the country,” explained McComiskey, who plays a little golf. He also is a member of the local Rotary Club and serves on the Giles County Economic Development Commission.

McComiskey attributed his early success to being mentored by his father, grandfather, and an uncle. “It’s been ingrained in me…Do it right the first time, and do it the best you can.”

“I was lucky enough to have the three smartest people I’ve ever known related to me,” he added.

He admits he’s also driven by the “fear of failure” and pushes himself.

“I’m a caretaker of what we do,” said McComiskey. “I see myself as one of the people who are here every day. It’s a responsibility I have to the teammates I have here to see if we can continue this until it’s time to get off this ride.”

“I want to see where we are in five years, 10 years. That kind of excites me. How can we get better at what we do? I’m always looking for ways to improve.”

Editor’s Note: For more information on Go Fast or its product line, visit www.gofastmfg.com or call (800) 854-7439. For more information on JM Forest Products, call (931) 424-6097.