White & Company LLC, a consulting and software development firm, has recently released versions 3.2 of Best Pallet™ pallet design/analysis software and Best Load™ supply chain simulation software. Now users have the ability to load any shipping mode with mixed- sized empty pallet stacks and mixed unit load SKUs for LTL and MTL shipping efficiency.

“Pallet manufacturers will now have the ability to automatically or manually generate mixed truckload layouts of mixed-sized pallet stacks,” said Braden White, director of technical services.

While there are a couple other programs out there that fit unit loads to shippers, this is the first software in the industry that can perform this function for mixed sized pallets, he said. Prior to the new release, Best Pallet only calculated load layouts for one pallet size.

Generating mixed load or pallet size layouts is typically done by hand, said White. For example, a manufacturer or shipper has to take the standard dimensions of a truck, such as a 48’ flat bed, or a shipping container, and then sketch out how many different sized pallets or loads they can fit.

“Now this feature of Best Pallet and Best Load allows pallet manufacturers to do this in a more automated fashion,” White said.

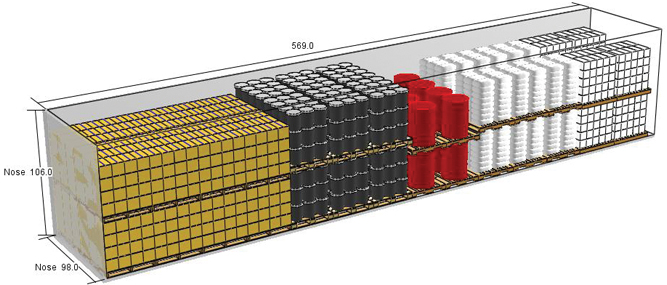

The software knows shipper dimensions and load limits – whether it be a flat bed, dry van, sea container, rail car, air freight or some other option. It takes the dimensions and calculates how many of each pallet or unit load size will fit in the designated shipper’s container.

For pallet stacks, users can upload up to five different pallet design files, and then just select how many of each they need to ship with any needed height restrictions.

After they load each design and select the quantity, Best Load or Best Pallet will then geometrically fit that quantity to the shipper. Then you select the second design file and put in the quantity the customer needs for the shipment, explained White.

The chosen designs are automatically arranged to maximize space utilization and the area of any void spaces are computed for load bracing materials. “In situations where there are void spaces, you want to develop load bracing materials or dunnage to prevent load shift,” White said. “You can also manually maneuver the pallet stacks or unit loads if you want.”

The software generates high-quality, 3-D graphics that give the coordinates of each pallet stack or unit load. Best Load works with both pallet stacks and unit loads, while Best Pallet works only with pallet stacks.

The new software features were driven by customer needs and requests, according to White. “Very commonly a shipper contains multiple unit loads for pallet sizes. Also pallet manufacturers are typically going to send a trailer to one customer and in doing so they want to replenish with more than one size.”

Anyone interested in trying the new software version can download the trial installation for free from White & Company’s website and access the MTL feature in the tool menu of Best Pallet or Best Load. For more, visit www.whiteandcompany.net or call 855/552-1158.