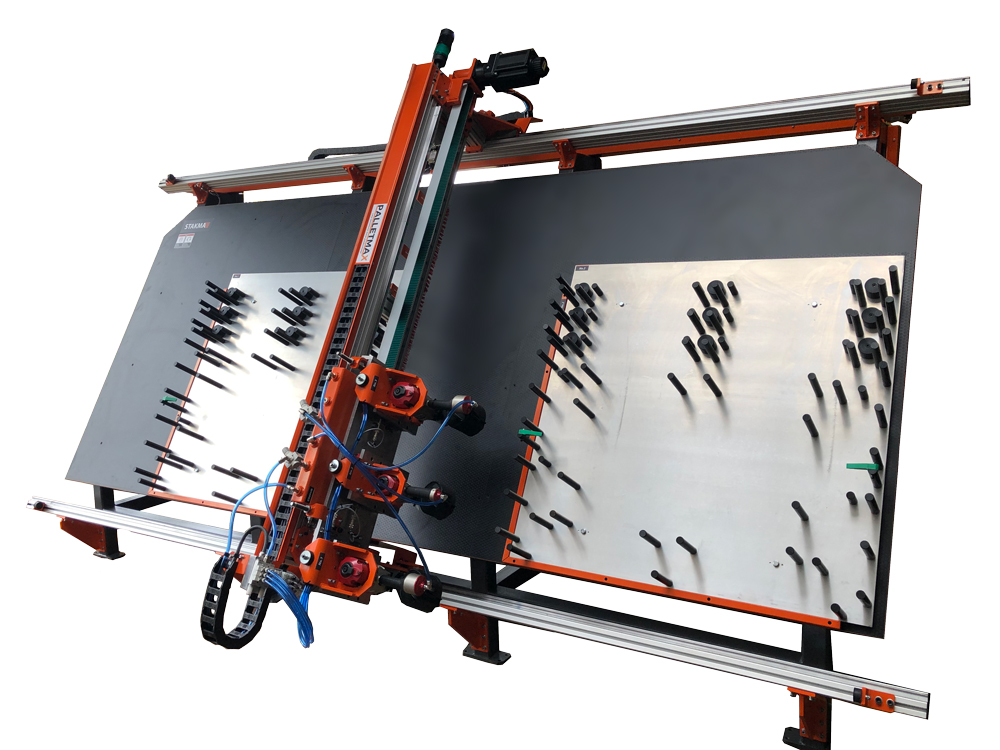

More than just an automated jig, the PalletMax by STAKMA combines easily removable pattern templates and automated nailing to ensure ergonomic, labor-saving production. The PalletMax can produce 400-1,200 pallets per eight-hour shift with two operators depending on the pallet size and complexity. The machine can easily produce 400-600 Europallets per shift.

The PalletMax features replaceable pallet templates which can be uninstalled by removing four bolts of each top & bottom corners. Depending on the speed of the operator, these templates can be changed in about five minutes or less.

“We are a family business located in Lithuania and have sold 140 machines in Europe, Thailand, South Korea and Australia,” said Mantas Zimnickas, president of STAKMA. “We are just entering the U.S. market with our first installation going into a pallet company in Illinois in the fourth quarter of 2023. Our systems combine the best of automation with the flexibility of human operators while reducing the wear and tear on workers.”

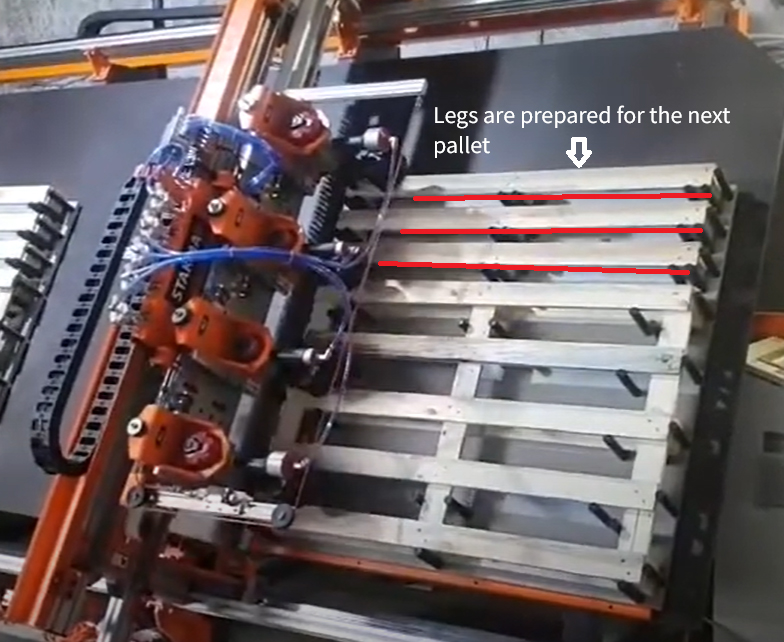

The process is simple. One operator places boards on the jig/table, which is angled to eliminate bending over by the worker. Boards are placed so that the top deck and bottoms are nailed at one time. While the operator builds one pallet, the nailing head moves around on a track and nails the main connection joints for a second pallet. The nailed pallet is then removed or turned over for nailing the other side. The nailing head does not use robotics, instead it moves over the decks to be nailed taking one second to nail each connection.

Mantas explained, “Our equipment makes the work easier for employees. There is no need to hammer pallets, the installation does this work for them. Easily and quickly changeable pallet templates allow you to quickly adjust the equipment to produce different pallets.”

The primary model offered for sale in North America is the PalletMax. The PalletStar is a more automated system. It requires only one operator to place boards while a robot removes and stacks finished pallets. The only difference in PalletMax models are the nailing gun variations and length of the table. See model specific information below:

PalletMax 4500 working length: 3800 mm, width: 1800 mm.

PalletMax 6000 working length: 5200 mm, width: 1800 mm.

PalletMax 7000 working length: 6200 mm, width: 1800 mm.

PalletMax 7500 working length: 6700 mm, width: 1800 mm.

PalletMax 8000 working length: 7200 mm, width: 1800 mm.

PalletMax 9000 working length: 8200 mm, width: 1800mm.

This machine offers automation without a lot of programming or operator know-how. Once the proper pallet pattern is placed on the gantry, select the proper program and hit start. It’s that simple. The nailing head is precision controlled and motorized to efficiently nail various designs. Up to four nail guns can be added to the nailing head. Features include automatic bearing lubrication, jumbo nail magazines and custom-sized machines. STAKMA uses MAX or Bostitch nail guns.

Each STAKMA machine comes with a one-year warranty. New units are available for delivery in 3-4 months. The first U.S. installation is currently underway, and STAKMA is currently looking for distribution partners in the United States.

All STAKMA pallet nailing solutions are produced with well-known, off-the-shelf brands. This make obtaining parts and servicing systems easy. Mantas said, “In most cases, customers can buy parts directly from suppliers in their local area.”

Pallet size capabilities differ depending on the size of the nailing table. The largest sizes range from 3800 mm to 8200 mm in length with 1800 mm in width on the PalletMax 9000. If you are looking for an automated solution for oversized pallets, the PalletMax and PalletStar are good options.

To see videos of these units in action, visit STAKMA on YouTube at https://www.youtube.com/@STAKMA. Watch a demo of the PalletMax 4500 at https://youtu.be/qL5qE1p6EiI?si=XyiIVJiYjE-v-wqN

PALLETMAX Series benefits:

• Operating system with automatic nails counting

• Simple, intuitive operating control with 15” screen

• Easy to use operator new pallet training

• Online service for easy maintenance

• High productivity and economic efficiency

• Excellent ergonomic and operating convenience

• Simple & fast new pallet dimensions change

For more information, visit https://www.stakma.com/en/ or e-mail mantas@stakma.com.