The economic slowdown has caused many companies to hold lumber in inventory longer than usual.

The longer dry lumber remains in storage, the greater the potential for moisture gain and a powder post beetle infestation.

It seems that every spring the question comes up as to whether kiln drying kills powderpost beetles and if one can determine exactly when the wood became infested.

Usually a beetle infestation is not noticed until the adults emerge out of a finished product — commonly flooring already installed in a home. The homeowner wants to know how the beetle got into the flooring, if they will infest other wood in the home, whose fault is it and how do they get rid of it.

There is a great deal of information published about what to do when powderpost beetles are found in wood products in homes.

I would like to focus this column on how the industry can prevent infestations in lumber. To answer that question we must know: what are powderpost beetles, how do they infest lumber, how long does it take for them to emerge, does kiln drying kill the insects, and what are the prevention strategies.

Three Beetle Families

There are three distinct families of powderpost beetles in the U.S.: the true powderpost beetles (family Lyctidae), the false powderpost beetles (family Bostrichidae), and the deathwatch beetles (family Anobiidae).

Lyctidae

The lyctid beetle most commonly infests large-pore hardwoods, like oak, hickory and ash; however, they have been known to attack black walnut, elm, locust, maple, osage orange, persimmon, poplar, sycamore, sassafras, and cherry. Imported tropical hardwoods such as mahogany are also prone to attack.

Lyctids typically infest well air dried or kiln dried hardwoods that are less than five years old. When adults emerge from the wood they are 3-5 mm in length and leave a very fine loose powder, known as frass, around the exit hole. These exit holes are circular and very tiny 1-2 mm in diameter. The average life cycle varies between six to 12 months.

Anobiidea

The anobii beetle will feed on hardwoods (such as maple, beech, or poplar) or softwoods (commonly pine). The usually attack older wood with higher moisture contents (typically moisture contents below 13% are unsuitable for anobii development or re-infestation. The adult exit hole is 2-3mm in diameter, and they produce a powder with a pellet type of frass. The life cycle of these beetles is between one and five years.

Bostrichidae

The bostrichid beetle also feeds on both hardwoods and softwoods. It prefers wood that is less than 10 years old. The adults range between 3-7mm in length and their exit hole can be up to 3mm in diameter with tightly packed, grainy frass. These beetles are commonly found in tropical hardwoods such as lauan and mahogany.

The vast majority of damage in lumber is done by the lyctid beetle, so the remainder of this column will focus on its lifecycle, habits and prevention.

Infesting Lumber

An infestation begins when an adult female lays her eggs on the surface or slightly under the surface of wood. Typically, the eggs are laid in the large pores present in ring porous hardwoods.

While powderpost infestations have been noted in lower moisture content lumber, most infestations occur in lumber between 9-15% moisture content. Hence, dried lumber that has picked up moisture and well air-dried lumber are prime candidates for infestation.

The damage is done when eggs hatch and the larvae being to create tunnels in the wood as they feed. These larvae generally bore parallel to the grain, extracting starches in the wood as a food source. These starches are only present in the sapwood; hence, the larvae only attack the sapwood.

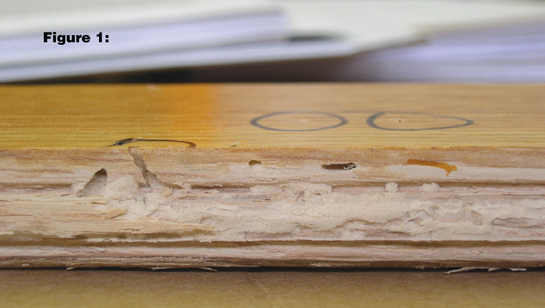

They reduce the wood to a fine powder, called frass, as they digest the starch. The damage can be extensive, as shown in Figure 1. When the insects reach the adult stage, they emerge from the wood, leaving holes and frass behind. When you see the holes and powder on lumber, the damage already has been done. While the larvae attack only the sapwood, adults may emerge from the heartwood.

Determining When

The eggs of a lyctid beetle typically hatch in one to three weeks. The lava stage can last between a few months to several years, with the average being nine to 12 months. The pupa stage lasts about two to four weeks; afterword the insect will emerge from the wood as an adult. The rate of development is influenced by the starch and moisture content and temperature. Therefore, it can be difficult to determine exactly when the infestation occurred.

However, an infestation must have occurred at least three to seven months prior to the emergence of an adult from the lumber.

Kiln Drying

The process of kiln drying lumber when temperatures used are a least 130 degrees Fahrenheit or higher has been proven to be effective to kill lyctid in all life stages.

While the time required for lumber to remain at temperatures of 130 degrees varies based on the lumber thickness and humidity used, these time periods are all less than 24 hours. Most standard kiln schedules include several steps well above 130 degrees for a time period that exceeds the minimum sterilization standard.

The potential for problems with sterilization in the kiln drying process occur when lower temperature kiln schedules are used or if kilns are not in proper working order, which can be determined and prevented by good quality control in drying operations. A quick check of the kiln control chart is one good way to determine if proper temperatures are achieved. Also, poor air-flow or low temperature zones in a kiln will usually also result in high moisture content variability within a load.

Prevention Strategies

Good general hygiene in the lumber yard and storage areas is a must to prevent powderpost beetle problems. Old lumber, stickers and bolsters in the yard or hidden in old inventories are often a culprit of infestation problems.

Prevention strategies also include the application of first-in, first-out inventory management. Maintaining moisture contents between 6-8% in hardwood lumber will also help as most beetle infestations occur with lumber that has picked up moisture to between 9-12%.

Since the lyctid beetle uses the sapwood of lumber as its food source, quickly moving wood with high sapwood contents can also be beneficial. In my experience, almost all infestations originate in a stored pack of lumber that is long forgotten and spreads to more valuable and recent inventory.

If you believe some material is infested, it should be removed immediately and heat sterilized to prevent further infestation. An example of effective heat treatment schedules is provided in

Table 1. Heat sterilization is the most effective method of killing beetles in all life stages in wood.

Treatment with insecticides is occasionally done on well air-dried material. Surface treatments of liquid insecticides by dipping, spraying or brushing can create a toxic barrier that kills beetles. However, these topical treatments only penetrate a few millimeters into the surface and will only kill larvae or emerging adults as they come into contact with the pesticide. Also, when the wood is planed, the planer shavings and dust will contain the pesticide, a potential health hazard for employees.

Summary

While there are three beetle families considered as powderpost beetles, the lyctid beetle is responsible for the majority of problems in dried hardwood lumber. Practicing good hygiene and moisture control in stored inventory will go a long way to preventing powderpost beetle infestations. Determining the exact time and location of infestation can be difficult; however, the kiln drying process, if done with temperatures at or exceeding 130 degrees, kills the eggs, larvae, pupa, and adult beetles. I recommend that kiln control charts be kept with other quality control information so that a company can demonstrate, should the need arise, that the sterilization temperatures were reached in the drying process. Make sure that if lumber needs to be stored for any period of time that it is done so in a clean environment and that low moisture contents are maintained.