Reviewing a recent list of citations given to a pallet company by the Occupational Safety and Health Administration (OSHA) brought to mind the importance of good sanitation and good housekeeping. There were a number of violations including: guarding, guard railing, confined space, and floors not being clean or dry. Previous columns have explored guarding but not sanitation and good housekeeping.

Maintaining a clean and clutter free worksite will reduce the potential for accidents and also can assist in boosting productivity. Overall facility cleanliness of walkways and egress, garbage handling and disposal, and basic cleanliness of public spaces are important factors toward employee health. This includes breakroom, restroom and food storage areas as well as the production floor. Trip hazards and sanitation can also result in fines from OSHA.

There are a number of OSHA standards to keep in mind, primarily OSHA standard 1910.141 for sanitation in general industry and OSHA standard 1915.81 covering good housekeeping. During workplace safety inspections, it is a good idea to always inspect points of egress, walkways, facility breakrooms and restrooms, for good housekeeping and sanitation. These locations are almost always found to be non-compliant to OSHA standards. Let’s take a look at each specific workplace area separately.

Egress and Walkways

Egress and walkways must allow for safe passage, and poor housekeeping practices are often the cause of blocked walkways, egress and exits. The accumulation of garbage, boxes and other debris, through improper disposal and storage, can prevent safe egress to exits. This not only creates an obstacle during an emergency evacuation, it also provides combustibles for fire growth in an industrial fire. Poor housekeeping is also a leading cause of slips, trips and falls in the workplace. Keeping egress and walkways clean, dry, and cleaning up spills promptly will prevent accidents, and assure safe egress in the event of an emergency. See Sidebar 1 for a complete list of egress and walkway requirements.

Food Storage and Eating Areas

Employees store and eat their food in about every area that can be imagined. Unknowingly, they may expose themselves to diseases, illnesses and poisoning from chemicals, such as lead. Food containers and food items cannot be stored or consumed in areas where food can be exposed to toxic chemicals. This includes work areas and restrooms.

OSHA covers these requirements in 1910.141(g)(2) and 1910.141(g)(4).

Food storage and eating area exposures to dust, chemicals, sawdust, dirt, fumes, gases, or human wastes are all forbidden under the standards. Where employee workstations have such exposures, the employees cannot be allowed to store or consume food or beverages in these areas. And employees can never be allowed to take or consume food or beverages in a restroom.

In OSHA standard 1910.141, OSHA requires a safe and sanitary location to eat food at each worksite. Breakrooms are a focal point for employees to gather, and are almost always found in an unsanitary condition. Unfortunately, most employees do not self-regulate their housekeeping. Tables are often found to be dirty, stained by spilled food or beverages, littered with magazines, and cluttered by food wrappers and residue. Frankly, most of the breakrooms that I see during inspections would not be a place that I would want to sit and have lunch. (See figure 1)

In figure 1 the breakroom table is relatively clean, but as you can see there are open food containers left out in which bacteria can reside. The other health issue would be that multiple employees are sharing food, in this case a bag of chips, an easy way in which a foodborne illness could be spread.

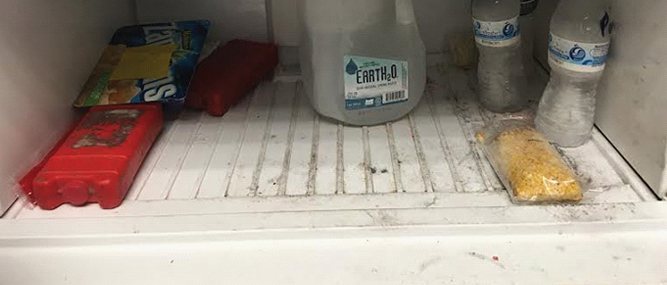

Hepatitis can easily be spread when sharing food, and even illnesses such as the common cold or flu could be transmitted in such a way. Refrigerators are often found to be even in a worse sanitary condition. It is not uncommon to find mold growth within a refrigerator located in a breakroom. Employees leave food containers, lunch bags, and uncovered food items throughout the refrigerator and freezer compartments. (See figure 2)

In figure 3 you can see mold growth in the freezer compartment of a breakroom refrigerator.

Obviously, these unsanitary conditions are not limited to the table and refrigerator, this is also a frequent problem with microwave ovens, sinks, floors and garbage receptacles.

Poor housekeeping leads to bacteria growth, and also attracts insects, and rodents which spread disease. In other words, employees are creating an unsafe and unhealthy environment, and the employer is allowing this exposure to be present. It is not the employees that will be cited, it is the employer that receives the OSHA citation.

Each workplace needs to have a cleaning schedule for their breakrooms and other eating places, such as areas provided for employees to eat outside of the building. You can assign staff members or add it to the janitorial responsibilities, but these areas must be kept in a clean and sanitary condition at all times.

Garbage

Overflowing garbage containers are a frequent hazard found by OSHA compliance officers. Poor garbage handling and disposal practices can result in disease and illness transmission, insect and rodent attraction, fire hazards, and can block egress.

Garbage must be properly discarded each shift, or as needed to reduce hazards. Garbage containers that are not emptied in work areas often result in industrial fires. Garbage and combustible materials within create a source for a fire when an ignition source, such as a spark from a grinder, is introduced. These garbage containers are also a point in which spontaneous combustion can occur. One oily rag, towel or piece of paper can spontaneously combust when improperly discarded in a garbage container. In workplaces where oily rags are creating in the work processes, an airtight metal container must be provided for disposal of oily or dirty rags.

Hygiene & Restrooms

Poor hygiene practices have led to many exposures to diseases, common illnesses and chemical poisoning through consumption of poisonous chemicals. Training your staff in proper handwashing and food handling procedures is important. There have been many documented poisonings from employees handling chemicals or materials containing lead, and then failing to properly wash their hands before eating. This is an easy route of chemical exposure through consumption. Chemicals are passed from the employee’s hands onto their food items, and then inadvertently consumed. Train your employees to wash their hands before and after eating, and before and after going to the restroom. Posting reminders in break areas, and on restroom doors is a good way to remind them. See OSHA standard 1910.141(c)(2)(i) through 1910.141(d)(3)(I) for OSHA’s bathroom requirements.

Restrooms are required to be provided for employees in the workplace, and it doesn’t matter if the workplace is within a structure, or out in a field. It is not uncommon to find disgustingly filthy restroom facilities in an industrial facility. It is not acceptable to find garbage overflowing, wash basins covered with dirt and grime, toilets covered with human waste, urine on the floors, and the toilet paper and wash towel containers empty. All of which will result in an OSHA health hazard citation. The OSHA standards listed under Hygiene, also pertain to the requirements in a restroom facility.

Having an adequate number of restrooms / water closets for your employees is also a requirement, Refer to OSHA’s Data Sheet – OSHA SANITATION RULES: THE STRAIGHT POOP. Keep in mind that OSHA says the number of facilities “provided for each sex shall be based on the number of employees of that sex for whom the facilities are furnished.”

A workplace that is sanitary, and has good housekeeping practices, will be rewarded with better morale, a healthier workforce, less workplace injuries, and fewer OSHA citations. These rewards also translate into a more efficient and productive workplace.

Editor’s Note: Jary Winstead is a safety consultant, author and trainer who serves a variety of industries including the forest products sector. He owns Work Safety Services LLC and can be reached at SAFEJARY@gmail.com.

Sidebar 1

Walkway and Egress

OSHA Requirements

1915.81(a)(1) The employer shall establish and maintain good housekeeping practices to eliminate hazards to employees to the extent practicable.

1915.81(a)(2) The employer shall eliminate slippery conditions, such as snow and ice, on walkways and working surfaces as necessary. If it is not practicable for the employer to remove slippery conditions, the employer either shall:

1915.81(a)(2)(i) Restrict employees to designated walkways and working surfaces where the employer has eliminated slippery conditions; or

1915.81(a)(2)(ii) Provide slip-resistant footwear in accordance with 29 CFR part 1915, subpart I.

1915.81(a)(3) The employer shall store materials in a manner that does not create a hazard for employees.

1915.81(a)(4) The employer shall maintain easy and open access to each fire-alarm box, fire-call station, fire-fighting equipment, and each exit, including ladders, staircases, scaffolds, and gangways.

1915.81(a)(5) The employer shall dispose of flammable and combustible substances, such as paint thinners, solvents, rags, scrap, and waste, or store them in covered fire-resistant containers at the end of each workshift or when the job is completed, whichever occurs first.

1915.81(b) Walkways.

1915.81(b)(1) In addition to the requirements in paragraph (a), the employer also shall ensure that each walkway:

1915.81(b)(1)(i) Provides adequate passage;

1915.81(b)(1)(ii) Is clear of debris, including solid and liquid wastes, that may create a hazard for employees;

1915.81(b)(1)(iii) Is clear of tools, materials, equipment, and other objects that may create a hazard for employees; and

1915.81(b)(1)(iv) Is clear of hoses and electrical service cords.