Every year workers come in con tact with equipment resulting in everything from a torn shirt to loss of an extremity to a fatality. In 2018, the Bureau of Labor and Statistics reported five fatalities in the Pallet Industry. Contact with equipment being one of the main root causes. The Wood Products and Manufacturing Industry had a total of 48 fatalities in 2018, which was nearly double that of the previous four years. Overall, across industries, an average of 700 employees lose their lives every year due to contact with points of operation. When reviewing the Occupational Safety and Health Administration (OSHA) report for most frequently cited standards for 2018, Control of Hazardous Energy (Lock-out Tag-out), and Equipment Guarding were the second and third most cited violations.

When looking back on my past inspections in the wood products industry, I can say without a doubt, that the control of hazardous energy and equipment guarding were two of the most common safety hazards found. This was very prominent in facilities with older machinery. Manufacturers have made it a point to incorporate safety systems and components on machinery for the control of hazardous energy and point of operation guarding. Isolation points and controls are more accessible, as well as factoring in various energy sources and eliminating point of operation exposures with less steps. Guarding equipment has also become a high priority for the manufacturers of new machinery.

Of course, we still have one unpredictable factor. Equipment manufacturers can incorporate every safety system possible to make the machinery used safer, but we still have the human factor. Workers can still by-pass safety devices, and fail to follow policies and procedures resulting in workplace injuries. This is why it’s so important that business owners and managers follow the requirements of the OSHA standards relevant to their workplace. When completing accident investigations, I find it all too common that there was a failure of management to either have the policies and procedures in place, provide the required training, or enforce their company’s policies and procedures that resulted in an accident. I can’t tell you how many times that a manager has told me that an employee had caused a close call several times previous to an accident, and management failed, because the policies or procedures had not been enforced. In the end, you must be able to prove that management did everything required and possible to prevent the human factor from causing the accident.

In the following check points, we will review the policies and procedures required by OSHA, as well as recommended safety program components for exposure controls, control of hazardous energy, and point of operation guarding. These check points can serve as self check points for your management and safety committee to assist them in finding areas that they can improve upon.

Complete a Risk Assessment to determine the hazards and risks associated with the workplace and the tasks performed. This will be used to eliminate hazards, and to determine the Written Safety Programs, administrative controls, engineering controls, training, and personal protective equipment requirements.

o Written Safety Programs – OSHA requires all workplaces to have written safety programs that meet the standards associated with the tasks performed and the hazardous exposures within the workplace. Written Safety Programs are a set of written documents that describe a company’s safety policies and procedures, including training, safety rules and responsibilities. The program is designed to provide guidance for your overall injury and illness prevention program. All programs must be re-evaluated at least annually to ensure that the programs are effective and meet the changing requirements of the workplace.

o Provide workplace safety training for all employees relevant to their job tasks. Safety training must be provided at the employee’s initial assignment and previous to their beginning work. All training needs to be thorough and documented.

o Complete routine safety inspections. Workplace safety inspections must be completed at least quarterly by either management or the safety committee. The inspection identifies deficiencies in OSHA compliance, identifies hazards and evaluates the company’s overall safety program.

o Provide annual and refresher safety training for employees. All safety training relevant to OSHA standards and in accordance to the Written Safety Programs must be provided at least annually. Training should also be provided in the event of near miss, and or accident trends, and when new equipment or processes are put into place.

o Enforcement. Safety programs and rules serve no purpose when not enforced. Management must ensure that employees follow safety program policies and procedures.

o Entanglement hazards. Ensure workers with long hair keep their hair up or in a net. Loose clothing alert: un-tucked or unbuttoned shirts, loose gloves, and loose sleeves can quickly become entangled in operating machinery.

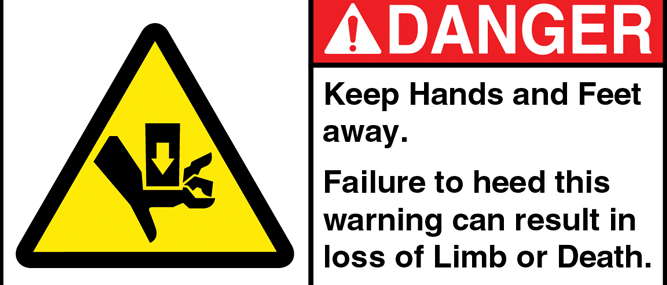

o Guard machinery. Ensure all machinery is properly guarded to prevent point of operation contact. See: OSHA Standard 1910.212 Machinery and Machine Guarding

o Guards must remain in place no matter what. Ensure employees know that guards are there to protect them from hazardous points of operation. Provide hazard awareness training and ensure employees know that guards and safety devices can never be by-passed or rendered inoperative.

o Visual warnings boost safety. Utilize signage identifying catch points, pinch points, rotating shafts, chains, gears, belts, blades, and other point of operation hazards. Mark off or install warning tape to restrict unauthorized access to hazardous areas.

Remember; signage cannot be used in place of guarding.

o Control of Hazardous Energy – Any time work places any body part near the point of operation, the machine must be placed under Lockout –Tagout procedures. This includes: unjamming, adjusting, cleaning, repairing, or performing other maintenance tasks. The machine must be isolated from all its energy sources. Make sure that all employees receive safety training for the control of hazardous energy. Employees within the production area will fall under either Affected Employees or Authorized Employees.

Authorized employee – a person that locks out or tags out machines or equipment in order to perform maintenance or service on that machine or equipment. “Authorized Employees” are trained and knowledgeable of the energy sources of the equipment, and the workplace’s LOTO policies and procedures.

Affected employee – an employee whose job requires him or her to operate or use a machine or piece of equipment on which service or maintenance is being performed under lockout or tagout, or whose job requires him or her to work in an area in which such activities are being performed.

Editor’s Note: Jary Winstead is a safety consultant, author and trainer who serves a variety of industries including the forest products sector. He owns Work Safety Services LLC and can be reached at SAFEJARY@gmail.com.