One of the most frequent causes of worker compensation claims today is Musculoskeletal Disorders (MSDs), particularly back injuries. With wooden pallets frequently weighing over 50 lbs., it comes as no surprise that lifting and handling such loads needs to be a consideration in eliminating loss time and worker injury.

The ability to understand what ergonomics is, how to identify some of the most common risk factors and what practical solutions to use, will help in reducing the number of MSDs. This translates into less workplace injuries, less time loss, more production and a healthier workforce. We all know how difficult it is to find and retain good workers. The pool of available workers continues to decrease making it all the more imperative to keep good workers, eliminate downtime and make your work environment as worker friendly as possible.

With today’s production and quality demands, it is extremely difficult to maintain the health and welfare of your workforce, making ergonomics even more important.

Analysis of the Typical Work Environment and Proper Worker Alignment

For many years, employers hired a new staff member, and he or she was instructed on how to perform a certain task. More often, than not, the employee was adapted to performing the job task. This was very common in the forest and wood products sector. Like most industries, the forest and wood products industry was production driven. When walking through a mill, employees were standing at a workstation that was an industry standard for height, standing on cold concrete, manipulating wood products as they moved down the conveyor or chain.

It’s not shocking that having an employee stand on cold concrete, while lifting and twisting all day, results in a lot of soft tissue injuries, and high worker compensation costs. Countless injuries to hands, wrists, elbows, shoulders, neck, back, knees and feet were the result.

When looking back at various production environments including forest products facilities, all of the components of production were designed to be in-line, and organized according to the product. We never thought that keeping the worker’s body in-line and the workstation organized for the worker to be important.

What is Ergonomics?

Ergonomics is essentially the science of arranging the job task to fit the worker. Instead of adapting the worker to the job task, we adapt the job task to fit the physical worker.

Professional ergonomists use physiology, anthropometry and biomechanics to understand how to fit the job to the worker. Once there is an understanding of body mechanics, professional ergonomists focus on engineering controls. Equipment that is “ergonomically engineered” assists in reducing the ergonomic risk factors of the worker. Ergonomic engineering has come a long way; Padding to reduce fatigue and injuries due to walking and standing on cold concrete. Hammers that are balanced, and have handles formed for lessoning impact, and for better wrist positioning. Padded handles on hand tools that reduce impact. Shoes that provide both cushion from impact, and arch support. Workstations that are adjustable height for the workforce. Adjustable tables, that keep the product between the chest and waist level of the worker. Conveyors and chains that do not require repetitive product handling by the worker. These and other developments can help you reduce worker strain.

Statistics on MSDs

According to the Bureau of Labor and Statistics (BLS), MSDs are a frequent cause of workplace injuries, accounting for 31% of all workplace injuries in 2015. The leading major event or exposure resulting in occupational injuries or illnesses for all private and public sectors in 2015 was overexertion and bodily reaction with 376,190 cases accounting for 33% of total cases.

The leading nature (type) of injury or illness in 2015 for all ownerships was sprains, strains, or tears with 421,610 days-away-from-work cases accounting for 37% of total cases. The 2015 rate was 38.0 cases per 10,000 full-time workers, down from a rate of 38.9 in 2014. Workers who sustained sprains, strains, or tears required a median of 10 days away from work compared to eight days for all types of injuries or illnesses.

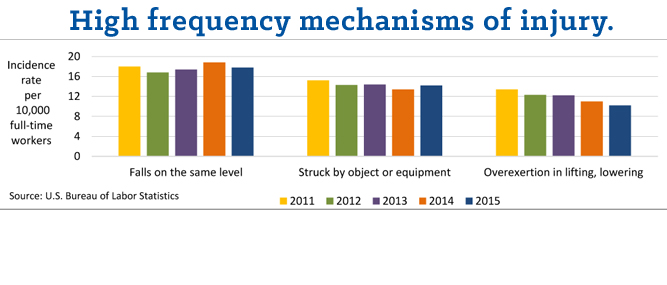

The graph on page 50, provided by the BLS, compares these injuries to other high frequency mechanisms of injury. As you can see, the rates of MSDs has been going down according to the BLS.

Risk Factors

Risk factors can be found in any job task or workstation. Obviously, certain job tasks potentially have a higher risk factor than others. A worker that is handling pallets all day, is at considerably higher risk for back and shoulder injuries, than someone handling a lower weight and/or smaller size object, such as a cardboard box or bucket. It is important to note that MSDs can occur in almost any lifting or moving action due to repetitive motion, or when the workstation is not organized ergonomically.

Risk for MSD’s increase with the following tasks:

• Frequent manual material handling

• Exposure to extreme temperatures

• Exposure to excessive vibrations

• Repetitive motions throughout the work shift

• Awkward or stationary work positions

• Utilization of excessive force or localized pressure to perform tasks

• Unnecessary lifting of heavy and awkward items

• Improperly padded or adjusted seating

• Pounding

• Twisting

• Squatting

• Bending

• Improper skeletal alignment

• Eye strain

• Stretching

• Standing long periods or on hard surfaces

Most every workplace that I have seen has some MSD concern. Workers need to keep this in mind and follow best practices to reduce strain. Injury trends will be your first place to look. Your company’s OSHA 300 logs will provide you with specific information when it comes to mechanisms of injury. And an ergonomic assessment would be a great first step in addressing the MSDs in your workplace.

Symptoms of MSDs

Assessments frequently begin by a conversation with a group of employees asking them if they have experienced the symptoms of MSDs. And through the years, I have yet to find a staff that has had no symptoms to MSDs. Sometimes this results from activities outside of the workplace. But it is important to know the symptoms to watch for including: headaches, fatigue, aching, tingling, numbness, muscle tightness, cramping, burning sensation and pain.

Ergonomic Assessment

In order to determine how and what changes need to be made, you first need to assess the workplace, job task and workstation. There are many tools available; online checklists, your worker compensation insurance provider, and assistance from the Occupational Safety and Health Administration (OSHA). Most worker compensation insurance providers have ergonomists on staff to assist their insurers, and this is provided at no charge to their insurer. OSHA also has ergonomists on staff that can assist you in assessing the workplace, and again at no charge.

The worksheet on the left is a basic checklist that I have used to assess a workplace. The document is a workstation analysis reviewing the equipment, work surfaces, tasks, layout, and measurements of a workstation for the purpose of an ergonomic assessment.

When completing the assessment, and you find a high percentage of work hours falling under physical requirements, there is always room for improvement. Granted, some job tasks require a high demand of physical requirements, and that cannot be changed. That doesn’t mean that engineering controls and safety training cannot reduce your workplace risks for MSDs. In the next article, we will follow up and discuss workstation organization, ergonomics, safety training, injury prevention and safe lifting techniques.

Editor’s Note: Jary Winstead is a safety consultant, author and trainer who serves a variety of industries including the forest products sector. He owns Work Safety Services LLC and can be reached at SAFEJARY@gmail.com.

Workplace Ergonomic Assessment

Check each box that applies, and complete the applicable information.

Department:________________________Location:____________________________

Workstation Equipment & Tools

o Chair o Padded Adjustments: o Height o Back o Armrest o Tilt

o Foot Rest

o Computer Monitor Size ___________ Height______________

o Key Board Type___________Size________________

o Wrist Rest

o Tool Storage Distance from workstation________ Height __________

o Chemical Storage Distance from workstation________ Height __________

o Lighting o Overhead o Behind o In front o Florescent o Glare

o Pneumatic Tools Examples:_________________ ____________________

o Hand Tools Examples:_________________ ____________________

o Power Tools Examples:____________________ ____________________

Physical Requirements

o Shift times _____ to _____

o Shift Length ________ hours

o Break Periods ______—_______ ______—_______ ______—_______

o Task Rotations Available Example__________________________________

o Average Height of Workers ______’ ______”

o Lifting Average weight ______________ Heaviest weight____________

o Distance weight is carried ________ feet

o Height weight is lifted ________ inches

o Height in which materials are handled / tasks are performed _______ inches

o Distance to Focal Point ________ (Inches tasks are performed from eyes)

o Lifting Percentage of shift performed ________

o Twisting Percentage of shift performed ________

o Bending Percentage of shift performed ________

o Hand or Wrist Repetition Percentage of shift performed ________

o Walking Percentage of shift performed ________

o Standing Percentage of shift performed ________

o Sitting Percentage of shift performed ________

o Running Percentage of shift performed ________

o Squatting Percentage of shift performed ________

o Kneeling Percentage of shift performed ________

o Reaching Overhead Percentage of shift performed ________

o Foot Controls Percentage of shift performed ________

o Overhead Work Percentage of shift performed ________

Work and Standing Surfaces

o Bench / Table Height ___________ inches o Adjustable

o Concrete Floor

o Wood or Linoleum Floor

o Carpeted Floor

o Padded Floor Inches thick _______

Person completing assessment: _______________________________________ Date ___/___/___