The Environmental Protection Agency’s (EPA) last reported update of the Toxic Substances Control Act provided a total of 86,228 chemicals currently in use in this country. In order to ensure the safety of employees, it’s important that employers provide information to workers regarding the chemicals that companies use in the workplace.

In 2003, the United Nations adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). The GHS includes criteria for the classification of health, physical and environmental hazards, as well as specifying what information should be included on labels of hazardous chemicals as well as Safety Data Sheets (SDSs).

The Hazard Communication Standard (29 CFR 1910.1200 (g)), revised in 2012, requires that the chemical manufacturer, distributor, or importer provide SDDs for each hazardous chemical to downstream users to communicate safe use, handling and storage information to employees. Previously, SDSs were known as MSDSs or Material Safety Data Sheets.

What does all of this mean to you as an employer?

There are five major elements to the GHS that the Occupational Safety and Health Administration requires employers to comply with:

• Chemical Inventory – Employers are required to maintain a full inventory of all chemicals in the workplace

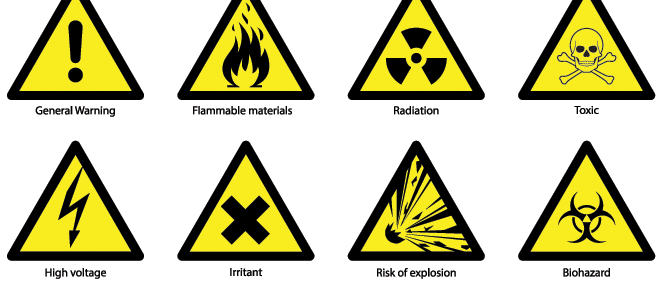

• Labeling – Employers must ensure that all chemicals are labeled in accordance to the GHS, and the nine pictograms identified in the standard to communicate the hazardous characteristics of the chemicals.

• Safety Data Sheets – Employers are required to update their MSDSs to the new SDSs

• Written Program – Employers are required to have written safety programs in place that identifies the workplace’s specific compliance to the standard. This includes who is responsible for compliance and training.

• Training – Employers were required to provide GHS training to their entire staff no later than December 1, 2013. Employers are also required to provide training at an employee’s initial assignment, and at least annually thereafter. The most important components of the training to include; chemical hazards related to the chemicals used, chemical safety and exposure controls, personal protective equipment, SDS interpretation, and identification of the nine pictograms designated under the new labeling requirements.

To assist employers in training, this article will cover SDS interpretation, and the nine pictograms of the GHS. These are the two biggest changes, and the most important to cover for training. To comply with the standard, SDSs are required to be organized with the same 16 sections, and in the same order. This makes it easy for employers and employees to obtain information about the chemical.

The 16 sections are as follows:

Section 1. Identification

Section 2. Hazard(s) identification

Section 3. Composition/information on ingredients

Section 4. First-Aid measures

Section 5. Fire-fighting measures

Section 6. Accidental release measures

Section 7. Handling and storage

Section 8. Exposure controls/personal protection

Section 9. Physical and chemical properties

Section 10. Stability and reactivity

Section 11. Toxicological information

Section 12. Ecological information

Section 13. Disposal considerations

Section 14. Transport information

Section 15. Regulatory information

Section 16. Other information, including date of preparation or last revision

For more information on these 16 HAZCOM sections, visit https://www.osha.gov/Publications/OSHA3514.html.

The nine pictograms to illustrate the chemical’s hazardous characteristics are:

Health Hazard

Hazardous characteristics

• Carcinogen

• Mutagenicity

• Reproductive Toxicity

• Respiratory Sensitizer

• Target Organ Toxicity

• Aspiration Toxicity

Flame

Hazardous characteristics

• Flammables

• Pyrophorics

• Self-Heating

• Emits Flammable Gas

• Self-Reactives

• Organic Peroxides

Exclamation Mark

Hazardous characteristics

• Irritant (skin and eye)

• Skin Sensitizer

• Acute Toxicity (harmful)

• Narcotic Effects

• Respiratory Tract Irritant

• Hazardous to Ozone Layer (Non Mandatory)

Gas Cylinder

Hazardous characteristics

• Gases under Pressure

Corrosion

Hazardous characteristics

• Skin Corrosion/ burns

• Eye Damage

• Corrosive to Metals

Exploding Bomb

Hazardous characteristics

• Explosives

• Self-Reactives

• Organic Peroxides

Flame over Circle

Hazardous characteristics

• Oxidizers

Environment (Non-Mandatory for OSHA)

Hazardous characteristics

• Aquatic Toxicity

Skull and Crossbones

Hazardous characteristics

• Acute Toxicity (fatal or toxic)

Editor’s Note: Jary Winstead is a safety consultant, author and trainer who serves a variety of industries including the forest products sector. He owns Work Safety Services LLC and can be reached at SAFEJARY@gmail.com.