Pallet Express is a successful pallet recycling company located in Liberty, North Carolina, about 20 miles from Greensboro. The company continues to grow with the support of its 170 employees, a focus on meeting the needs of its customers, as well as through astute attention to equipment maintenance and selection.

“The key to our success is teamwork with all of our employees,” explained Lynn Bell, Pallet Express vice president and joint owner. “We’ve got a lot of people who have been here for 15 years or more.” The company operates 20 tractor trailers, two straight trucks and around 250 trailers, serving a customer base located within a 150-mile radius of their site.

A focus on teamwork enables the company to successfully fill customer needs. “We are customer oriented,” Bell said, “so we strive to get the customer requests out to them as soon as possible.”

Pallet Express moved from Greensboro to its present 30-acre location in late 2013. The relocation was made necessary when the state purchased its previous property as part of a highway construction project.

About four months were required to prepare the new site for pallet recycling operations. The location had previously housed a modular building manufacturing company, which had gone out of business several years earlier. The actual move took place over a weekend, starting on a Thursday afternoon. The company was already up and running at the new site on the following Monday morning.

Regrind Program Offers Considerable Savings

Bell stressed that the smooth relocation was made possible by the support of several key people. One of those essential team members is David Newkirk, the company’s maintenance manager. Newkirk’s background includes machinery design and building, general fabrication, welding and “anything to do with metal.” He joined the company around five years ago.

At that time, Pallet Express was not reusing its notcher inserts, which Newkirk saw as an opportunity. “Every large business I had worked with in the past always had a program in place where they sharpened their inserts,” he explained.

Newkirk had the opportunity to meet John and David Lieber of Profile Technology at a trade show in Charlotte. “I liked those folks a whole lot, and they are pretty straightforward with their business,” he recalled.

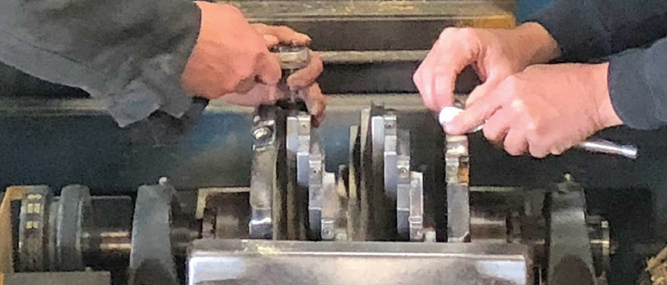

“I talked to David (Lieber),” Newkirk continued. He explained that Pallet Express goes through a lot of notcher inserts and they had been hanging onto the used ones because they are carbide. “I asked him if they offer a regrind program, and sure enough, they did.”

Profile Technology offers multiple grades of wood cutting and Nailbuster® grade carbide inserts which can be inserted into customized heavy-duty tool bodies to create highly durable and impact-resistant tooling for machining reclaimed lumber, including material with embedded nails.

Profile Technology first introduced machining recycled stringers with Nailbuster® carbide in 1991. “Since then,” Lieber said, “we have developed a complete line of cutting tools and multiple carbide grades for machining boards, stringers, cants, etc. with nails. These operations include notching, surfacing, resizing, hogging, chamfering, strap notching, crosscutting, and ripping.”

In 2015, Pallet Express began using Profile Technology’s Nailbuster® inserts and regrind program. “It has been super beneficial to us,” he said. “We have cut our cost considerably by regrinding the old notcher inserts and just having Profile Technology regrind them for us. When we get to a point where they are out of tolerance, then we have to buy new.”

Lieber said all notchers aren’t built the same. They all have their unique operating ID and idiosyncrasies. “We work closely with our customers to provide multiple grades of quality inserts, insert service program, and recommendations for improving notcher efficiency,” he explained. “Less expensive does not always mean lower cost per cut or cost of operation as there are many factors that play into the investment you made when purchasing the machine and the inserts you choose to put into the machine.”

Short-term cost gains create long-term expense and wasted time, Lieber emphasized. He cautioned that if you’re not purchasing your inserts for an indexable notching head from the tooling manufacturer, you are selling yourself short on savings and performance.

In the case of Pallet Express, generally, the inserts can be resharpened twice, depending upon when they are replaced. Newkirk will typically order between 1.5 to 3 months supply to ensure there is an adequate supply on hand. “I tend to overstock,” Newkirk said. “I never want to be caught short.” He either orders by email or telephones Profile Technology directly. Usually, delivery takes a day or two, depending on what time of day he places an order.

Early in the business relationship, Newkirk continued to compare prices but found the Profile Technology service program to be much cheaper due to the regrind program and the superior quality of the Nailbuster® technology. “There are a lot of inserts on the market, but they don’t meet the same high standards required by Profile Technology’s Nailbuster® inserts,” Newkirk said. “We are dealing with recycled pallets here. Notchers might have to grind through a nail or tramp metal. We don’t have any trouble with Profile Technology inserts. They have stood the test of time.” New insert usage is down 50% compared to before the program started.

On one occasion, Pallet Express was in urgent need of a complete notcher head assembly, inserts and shaft. Profile Technology quickly delivered a replacement. “David (Lieber) helped me out of a bind,” Newkirk said. “Their customer service is always timely.”

Pallet Express Introduces Sorting Automation

Pallet Express has relied on manual pallet handling for many years. After they moved to the new site, they made use of two conveyors that were available. The company sorts before repair. Unrepairable pallets are taken apart by one of several band dismantlers (the Industrial Resources Wolverine is their machine of choice). The material is used for repair or for construction of combo pallets, which are assembled in jigs.

Wood waste material is ground up for producing mulch. The company runs both Rotochopper and West Salem grinding equipment and utilizes Colorbiotics technology to produce colored mulch, which it sells under its Express Mulch brand.

A very recent improvement at Pallet Express has been the installation of an automated sorting line from Automated Machine Systems (AMS). At the time of our interview in mid-March, it had only been running for two weeks. One of the challenges in selecting a system was in finding one that would handle a large number of pallet sizes and categories within those sizes.

“Our sort operation is quite large,” Bell elaborated.” Adding the necessary equipment to fit the floor plan was a challenge. “We went through several designs before settling in on the right one for us. I would say that how AMS responded to our needs and concerns and the patience they showed while working through all the constraints was much appreciated.”

“Overall, our production numbers from the sort line have increased dramatically since it was installed,” Bell said. The system includes tipper, end of line stackers, as well as vacuum assist lifts, which enable the effortless handling of pallets. AMS systems are designed to address the ergonomic and workers compensation problems facing the pallet industry.

“The biggest challenges we face are employee recruitment and retention,” Bell stated, explaining the rationale for investing in automation. “It seems that the number of people willing to do this type of work has diminished over the years. The ones who do believe that they have what it takes find out real quick that they may have bitten off more than they can chew.”

The company has been forced to address the issue of how to get people to come and stay for the long term. “We have had to look into innovative ways to reduce the intensity of the work,” Bell offered. “We have added automation to certain operations, such as sort. This cuts down on the physical aspects of the job. The automation has helped some, but I still feel that finding punctual, quality employees is one of our biggest challenges.”

Pallet Express continues to grow, looking to suppliers such as Profile Technology and AMS to provide the automated equipment and consumables needed to help it deliver consistent quality to customers and to provide a better, more productive workplace for its team members. As Bell noted, “The main thing is our employees.” For Pallet Express as for the pallet industry at large, prospects for the future start with them.