CADIZ, Kentucky — When is the most opportune time for a sawmill to invest in new machinery and equipment? Before the lumber market heats up so that new systems are ready to go and the mill is positioned to cut when the uptick occurs, according to Donnie McCraw.

McCraw, the owner and operator of McCraw Lumber, invested in a new Brewer resaw system for his grade sawmill earlier this year. The Brewer resaw and runaround system began operating in March. It was about the same time when the grade lumber market started to retreat. However, McCraw is not deterred.

Some people in the industry may argue it is not a good time to invest in plant and equipment when markets are weak and prices are down. McCraw differs. “It’s better to do it now and have the equipment,” he said. “When this market turns around, you’re ready to saw.”

He would advise others to do likewise, he said. The market inevitably will turn around, noted McCraw. “It always has. We have our ups and downs in this business, and we’re in a down mode, but the market will rebound.”

McCraw Lumber has been in business for 34 years. Donnie McCraw Sr. is the sole owner along with his son, Donnie Jr., who operates an affiliated logging business, and his daughter, Joy, who serves as his secretary. The company is located in Cadiz in southwest Kentucky, about 85 miles northwest of Nashville, Tennessee.

The company produces rough sawn grade lumber — sold green — although this year it is cutting more low-grade products, notably railroad ties. “I have to go with the change in times,” observed McCraw. Although the company has been cutting more ties in recent months, McCraw still considers his business a grade lumber mill.

McCraw Lumber cuts about 21,000 board feet of hardwood per day. The company, with 14 employees, runs an eight hour shift, five days per week, year-round. It may cut red oak for a week, then switch to poplar, white oak, or other species, depending on its log supply. The company cuts hardwoods like red oak, white oak, maple, cherry, hickory, ash, poplar and walnut. Other species include gum, hackberry and sycamore.

McCraw relies mainly on gate wood – logs brought to the mill by independent logging contractors. He also buys logs from his son. The company buys logs ranging 8 to 14 feet long and down to 11 inches in diameter on the small end. The logs are sawn mainly into 4/4 lumber although the mill also cuts some 6/4 and 8/4. With a good grade log of red or white oak or other species, the mill will cut it all the way down to a 4×6 cant. For low-grade logs, the company is better off quickly cutting out the crosstie, pallet cant or other product.

McCraw, who prefers to sell his lumber production direct instead of using a broker, handles sales for the company. He sells his company’s lumber production to concentration yards that have drying operations. “We try to stay within a 200-mile radius,” he said.” He has done a lot of business with a nearby company but also reaches out to customers in Tennessee and Arkansas.

Prices for grade lumber, notably #2 and #3 Common, have been in decline this year, noted McCraw, although they have recently leveled off. Because of the decline in prices, it is more efficient for the mill to cut a cross tie out of a log then #2 and #3 grade material for the flooring market. “I have to look at what the markets are doing when I am sawing,” he said. The market began weakening in March and April but has reached a plateau for now.

Adjusting to the market has altered the company’s production significantly. In the past the company cut about one truck-load of crossties per month. Under current market conditions, the company is producing about three truckloads per week.

Fortunately, the market for crossties is good. “They’re pushing more for rails to get traffic off the highways,” said McCraw. “Our rail markets are going to stay strong.”

The sawmill has been equipped with a Mellot debarker, a Cleereman carriage with a circular head saw, a pair of band resaws, and a Pendu two-saw edger.

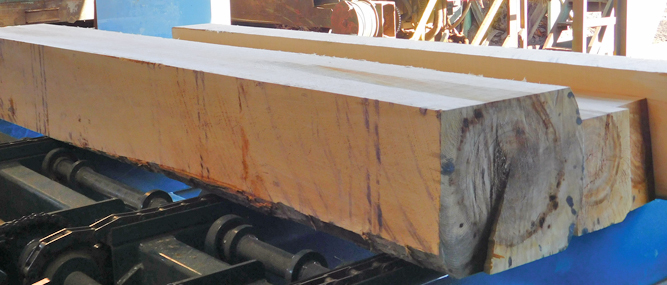

McCraw invested in the new Brewer grade resaw and runaround system in order to replace one band resaw. Brewer took one of the older resaws in partial trade on the new system, but McCraw has since idled the other remaining older resaw. “We want to saw as much on the Brewer saw as we possibly can,” he said, because of the thin kerf. The Brewer grade resaw runs a 5-inch wide blade with a 0.113-inch kerf.

“The Brewer saw is capable of sawing just like my head saw,” said McCraw. It can cut grade lumber of different thicknesses, crossties or pallet cants. “It’s as flexible as anything you want to do with it.”

“It’s a very, very excellent piece of equipment,” said McCraw. “The day I went and looked at it in their shop, I was overwhelmed with the type of material they were using.” What impressed him so much was the heavy-duty components and construction — the steel, rollers, bearings, chain and more.

Grade logs are being sawn on the new Brewer. Larger diameter logs are broken down on the head rig until they get to 18×18 and then are kicked off the Brewer. The blades on the Brewer are changed every three hours even if the blade is still cutting well, explained McCraw, because of the stress on the blades. Bartlett Saw Service supplies blades and sharpening services.

The new Brewer grade resaw has paid dividends for the company in a number of ways. It has reduced labor by one employee and reduced maintenance by running one resaw instead of two. “I try to run updated equipment,” said McCraw “Down time is what will kill you. It’s not the cost of the down time. It’s the cost of the production you get.”

“I run practically top notch equipment,” he added, from wheel loaders and trucks to sawmill machinery. For example, he trades in loaders and trucks every few years. “I’ve just found out it’s better to run the best of equipment than to work on equipment,” said McCraw.

Grading used to be done at the mill, but McCraw moved it into its own building. The reason is he does not want any bottleneck that slows lumber production.” It doesn’t stop my mill,” he explained. “My mill has to be productive…There’s not a reason there’s not some lumber coming down that chain at all times.” Lumber is stacked automatically and then moved via wheel loader to the grading building, which is equipped with a breakdown and unscrambler system for separating and transferring lumber to the green chain for grading.

Although the company weathered the recession of recent years, in all his 34 years, 2015 has been the most challenging, according to McCraw. “The main reason is we’re selling at a low price.” Overhead costs, like insurance, have risen. Fuel prices, although down somewhat, still remain high. Good labor is not cheap.

McCraw attributed the decline in grade lumber prices this year to weakness in overseas markets. “I hate to say that,” he said, but overseas markets have not been as strong this year as in recent years past, and the U.S. housing industry is still relatively soft. “We’re dependent on foreign markets…They’re not buying as aggressively as they have in the past.”

The view from the front porch of the office tells a tale. Twenty years ago, McCraw could eye eight sawmills from the front porch. “Today I’m the only one left.” As the region’s sawmill industry has contracted, so has the supply of loggers.

McCraw, who is a member of the Kentucky Forest Industries Association, has markets for all his residual materials – bark, sawdust and chips. “Every product off the mill has a home for it,” he said.

As he wrapped up the conversation about his business, McCraw’s thoughts were about people and his faith. “I’m so proud of some of the people that work for me. It’s just unreal.” One worker, the company’s head sawyer, has been employed there for 30 years.

In all his decisions, he said, McCraw asks God for guidance and wisdom. “I think I’ve just been well blessed,” he said.

Partnering to Develop the Iron Eagle

When Donnie McCraw decided to upgrade his sawmill, he wanted to build the next

generation of resaw, not simply purchase an existing model. This is why he selected Brewer Machine and Parts.

According to Darren Grogan, Brewer’s lead designer, “Brewer has produced grade systems in the past, but these were while the company was focused on pallets. This opportunity allowed us to jump full force into the sawmill industry.” Much of the Iron Eagle’s research and development was performed at McCraw’s mill so that tests were under continuous daily workloads, not in a limited factory environment.

The process began by identifying common limitations in today’s market. The fundamental conclusion was that simply adding size created a more stable base to improve saw performance and profitability. Thicker steel and over-sized components resulted in a massive 23 ton total weight and a 6-1/2 ton saw head. McCraw claimed, “It was just way more than what I thought I would be purchasing. There is no question that I’m going to be able to replace my previous two saws with this one Brewer.”

Focus then turned to functionality. Grogan explained, “The first performance issue was correcting the misnomer about wide band technology. Blade maintenance can easily be outsourced, so an internal filing room is not necessary even with 4 inch blades and greater.” Standard capacity was chosen for cants up to 18" wide x 18" tall x 18’ long. Other performance highlights include Delta Computer System’s setworks technology, electric VFD’s to maximize butt-feeding and a ridiculously lavish operator cab.

The final phase was advancing maintenance and longevity. The soft tilt board separator was the first break through with its patent pending technology which minimizes premature failures. Additional developments include machined shoulders on roll shafts; 4-bolt flange bearings; independent overlap chains to keep small timbers from jamming; no welded sprockets to shafts; and, include as standard features main disconnects and soft starters with overload protection.

McCraw comments on his involvement in the design process, “They’re good people to work with. Anything I wanted, they’ve been 110% on trying to work with me. I would highly recommend the Brewer resaws due to workmanship, the material and they’re wanting the best. I think they’ve got the best.”

In conclusion, Donnie McCraw invites everyone to observe his new Iron Eagle, “Now’s the time to be building these saws because the market will turn around. I will be ready, and I hope you are too. Anytime you want to come to Cadiz, Kentucky to see this saw running, you’re more than welcome.”

For more information on Brewer, visit www.brewermach.com or call 800/345-6516.