The future of pallet sales is rethinking something that pallet companies have been doing for decades – redesigning the pallet and unit loads to save money.

Wait, you may be thinking, “Don’t many pallet experts already do this?” And they do. The only problem is they are looking in the wrong place to find the biggest savings. They are looking at the pallet primarily instead of the packaging on top. And that’s a big mistake.

Given the recent focus on supply chain savings and reducing packaging waste, rethinking the unit load can help solve cost, environmental and supply chain challenges. The most prominent voice calling for a systems-based approach to unit load design has been Dr. Mark White (Ph.D.), professor emeritus of Virginia Tech University and the former director of the William H. Sardo Pallet Lab.

White is a world-renowned expert on transport packaging and pallets. Today, he helps pallet companies and packaging users around the world make better supply chain choices using two leading software products – Best Pallet™ and Best Load™. Beyond the software, White & Company also provides consulting services to major manufacturers, shippers and retailers globally.

Designing Better Pallets – Software Solution Overview

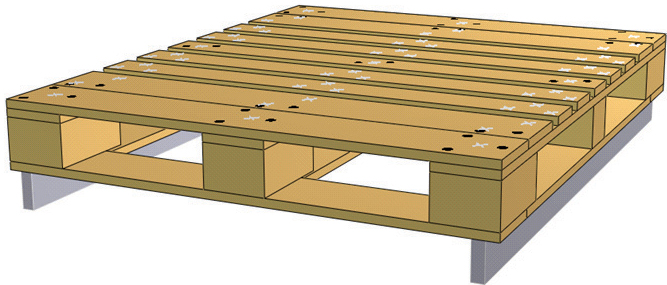

Best Pallet is used by pallet companies looking for a scientific-based, user-friendly structural design and analysis tool for all wooden pallets. Developed based on years of research and testing conducted at Virginia Tech, Best Pallet’s mathematical model relies on scientific principles of wood properties and systems-based design.

The software gives the user the ability to check the design of stringer pallets and block pallets. It can analyze all wooden pallet structures and calculate maximum safe load capacity, factoring the strength and stiffness of various designs. Best Pallet can check designs to identify pallet performance when supported by free-span racking systems, forked equipment, and when stacked in warehouse floor storage. Users can choose from any wood species, lumber grade, and moisture content along with freely specifying component quantities and dimensions. Once the proper design is configured, the software creates detailed specifications with quality 3-D graphics. These designs can be exported as PDFs or automatically integrated into common industry Enterprise Resource Planning (ERP) software.

Brad Watts of Starnes Pallet explained his experience with Best Pallet. He said, “We have been using the Best Pallet program for years. It is user friendly and can provide you with a lot of helpful information such as diagrams, load ratings, etc. It also allows you to provide your customers with professional information for their pallet needs.”

Graber Box & Pallet relies on Best Pallet to improve customer service and internal communication. Mike McMillan of Graber Box & Pallet reviewed the benefits. He said, “Best Pallet is a great tool to show customers the pallet we are quoting. They love getting a Best Pallet print along with their quote.” Internally, Best Pallet prints show the production team everything they need to know to get the pallet order right the first time. The company also keeps prints on file to quickly, visually be able to know what was done in the past for each customer. McMillan added, “It’s easy to change or tweak pallet specs using Best Pallet.”

If you want to research and design more than just the pallet, Best Load™ may be the tool for you. Utilizing systems-based design methodology, Best Load helps users reduce annual packaging spend by 8-18%.

The software uses modern 3-D, FEA, structural analysis techniques to simulate unit load supply chain operations and generate performance outputs such as maximum safe load carrying capacity for pallets, compression strength of corrugated containers, and maximum applied compression stress on virtually any unitized distribution packaging system.

Best Load gives you the ability to optimize unit load designs and shipping methods with advanced algorithms, and it can predict the containment force of stretch wrap.

White & Company offers these software products on annual subscriptions. Users like the interface of Best Pallet because it offers simplified operation and a very wallet friendly price tag.

Braden White, director of White & Company, said, “The big difference between the two software products are the capabilities and the price tag. Best Pallet loading conditions have been significantly simplified and do not include the packaging design and performance capabilities. However, Best Pallet still allows users to model full uniform or partial uniform loads, as well as concentrated loads. Best Pallet is perfect for users that only needs to predict pallet strength, and stiffness and durability.”

Although Best Load has more functionality and a bit steeper learning curve than Best Pallet, its extensive options enable users to make design changes modeling the mechanical interactions between the pallet, packaging system, load stabilizers and storage and handling equipment.

Joe Movic, manager of corporate programs for the Pallet Alliance, stated, “With its wide variety of packaging styles to choose from, Best Load has allowed us to more precisely model specific and unique unit-load applications that help us achieve the goals set forth by our clientele. Best Load’s detailed outputs help us clearly and accurately communicate our solutions to the end user as well.”

Many pallet users just want a cheaper pallet, but they may be costing themselves more money in the long run when it comes to total packaging spend and product damage. Dr. Mark White explained, “By tweaking a pallet design and making it stronger, you can show through modeling how you can reduce the total cost of the packaging on top of the pallet, which is almost always more expensive than the pallet itself.”

He noted, for example, CHEP has done a good job using our software to show customers how a more robust pallet design reduces total packaging spend. Mark added, “When you get to rigid packaging, and I’ll start with corrugated and go on up to plastic bottles and empty pales, you know, these items are very expensive because of the plastic. A pallet may cost $15-$20 or more. Empty corrugated boxes used in packaging are likely going to run $50-$60. Empty pales cost $300-$400 and bottles are more expensive yet. You can use the pallet to reduce the total packaging cost.”

New Software Features in Upgrades and Future Developments

White & Company is always working to make its software products better. The company plans to release version 4.1 of Best Pallet and Best Load in early 2022.

One of the newest features is comprehensive fastener specification and durability analysis. Users can specify different types of fasteners for the same pallet. This upgrade also allows users to compare side-by-side durability analysis for various designs.

White & Company has added Pallet Connect and Pallet Track to its list of pallet-focused ERP platforms that it integrates with for easy exporting of designs. Now, the software works with all three popular ERPs – PalMate, Pallet Track and Pallet Connect.

Best Pallet is available in both English and Spanish for its entire user interface and output screens. The company plans to introduce in the future full Mandarin Chinese capabilities.

Continuing to evolve with the supply chain, Best Pallet has expanded the capabilities of the software when it comes to concentrated loading, so not just uniformly distributed but single line loads, double line loads, triple line loads, etc. As pallet colors keep changing for proprietary designs, Best Pallet now offers a revised color palette that allows users to easily make custom color designations. Best Pallet has also added the size and complexity of designs it accommodates. It can now design pallets with up to 10 stringers and 36 blocks and plywood or OSB decking.

Some future planned improvements include more integrations with pallet nailing systems, corrugated box compression strength enhancements, and expanding containment force modeling for stretch film.

Another future addition to Best Load is primary packaging design within distribution packaging design. Right now, Best Load accounts for the compression performance of primary packaging inside of corrugated containers. In the future, the software will also allow you to design and fit the internal cartons, cans, etc. These changes will make Best Load even better when it comes to geometrically fitting various aspects of the unit load.

Years of Research Goes into Every Design

Why do pallet companies and users trust Best Pallet and Best Load? The reason is simple. It is based on the best research and expertise on the planet.

Between 1979 and 2007 when he retired from full-time employment with Virginia Tech, Dr. Mark White was responsible for maintaining and contributing to a database that houses huge volumes of research on wood pallets, packaging, wood research, and pallet performance and design.

Mark recalled, “I expanded the database to include packaging. In the 1990s, that’s when we started doing research on packaging design and performance – mostly distribution, packaging, and unit load design. Virginia Tech is known globally for this research and its database is the envy of the world when it comes to this kind of research.”

During this same period of time, Mark became the director of the Center for Unit Load Design, which later changed its name to the Center for Packaging and Unit Load Design at Virginia Tech.

Mark noted, “The lab, the software, the students, this is all part of my legacy.”

Research conducted at Virginia Tech has become the backbone of White & Company’s software products. He praised, “It’s a great relationship we have here between White & Company and Virginia Tech. Dr. Laszlo Horvath runs the Center and Lab today. I continue to work with him and mentor the graduate students studying for advanced degrees. Their research leads to new knowledge that White & Company builds into its software.”

White & Company is a corporate member of the Virginia Tech, Center for Packaging and Unit Load Design. Mark added, “Laszlo and his team have done a terrific job with building up both the research and instructional program.”

Dr. White credited those who came before him: Dr. E. George Stern, (First Director of the William H Sardo Jr. Pallet and Container Research Laboratory): Dr. Walter B. Wallin, (USDA Forest Service); Thomas Depew (Founder of Tier Rack Corporation) and of course William H. (Bill) Sardo Jr (Executive VP of NWPCA). All of these names are enshrined on the Pallet/Globe statue in front of the Pallet Lab at Virginia Tech.

White & Company is currently a division of Ongweoweh Corporation, sharing a successful management relationship since the acquisition years ago. Ongweoweh utilizes Best Load as a service to their many national pallet programs. Beyond the software, White & Company’s consulting business does audits to evaluate failure modes, assess cost saving opportunities, compliance issues with handling equipment and storage equipment, and design and physical testing programs.

Braden explained, “We follow the AADTI method here when it comes to consulting projects. We Audit, Analyze, Design, Test and Implement solutions. We use our software as well as work with Virginia Tech to conduct tests as needed for clients.” White & Company has consulted with major consumer brands, industrial manufacturing companies and retailers.

Part of the White’s relationship with Virginia Tech involves donating use of the software to the university for students. Dr. Laszlo Horvath, director of Center for Packaging and Unit Load Design, commented, “The Best Load and Best Pallet software donated by White & Company is an excellent addition to our packaging curriculum. Our packaging engineering students are using the software to design efficient unit loads to decrease the cost and increase the safety and sustainability of the palletized supply chain.”

Now, you can use the same software utilized in this leading packaging program and give it a try for free. If you want to start designing better pallets today, visit www.whiteandcompany.net or call 855-552-1158.