With 40 locations nationwide, FCA, LLC, recently announced the acquisition of Greentree Packaging and Lumber, a leading Texas-based wood packaging manufacturer and lumber distributor.

The move bolsters FCA’s footprint in the competitive industrial packaging sector and further enhances its service capacity across the United States. The company’s number of locations has more than doubled from a decade ago, when Pallet Enterprise last featured FCA.

David Wilsted, the CEO since 2014, first joined the company in 2009. He was promoted to executive vice president in 2013 and became CEO after founder Jeff Campagna (the C in FCA) stepped back from full-time company oversight.

Under Wilsted’s tenure, notable acquisitions have included Crate Tech Packaging in 2015, Wisconsin-based Transpak in 2019, Timber Creek Resources in 2021, and most recently, Greentree Packaging and Lumber.

“All of those acquisitions are part of FCA Packaging and operate as cohesive, one-company FCA Packaging facilities,” Wilsted explained. “Our customers have a national network of 40 plants, including packaging design centers, warehouses and customer-on-site facilities they can turn to for their custom packaging needs across the entire country.”

Aside from acquisitions, the company has also opened 10 new sites over the last decade. FCA facilities are deliberately located near key customers. Often, orders can be assembled and delivered in less than 24 hours. Talking to Wilsted, one quickly understands how deeply invested FCA is in customers and their “mission critical” products.

FCA, LLC offers a comprehensive range of custom industrial packaging solutions through its production facilities to leading original equipment manufacturers (OEMs). These offerings include wood, steel, corrugated, and hybrid products and are available in expendable, reusable, and returnable formats. The emphasis is on wood, but various materials are utilized to provide the best solution for each challenge.

Company Capabilities

Wilsted noted that customers increasingly demand better quality, accuracy and turnaround times in addition to custom solutions. FCA’s capabilities, he said, provide a strong match. The company is known for engineered wood products that deliver cost-effective, strong packaging solutions that are compliant with international standards. Its design engineering capabilities include modeling, prototyping and testing to meet particular customer requirements. FCA also emphasizes sustainability with its innovative hybrid (multi-material) products that combine durability and cost-efficiency to minimize environmental impact.

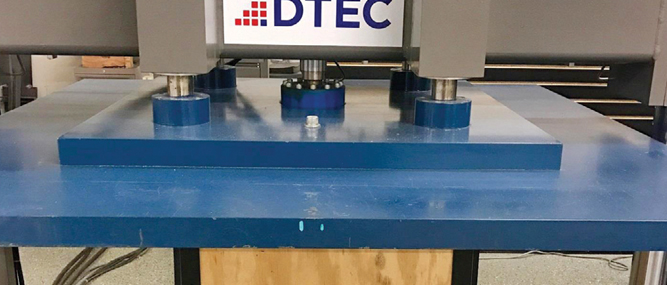

An integral component of FCA’s value proposition is its DTEC (Design, Testing and Engineering Center). The ISTA-Certified DTEC houses degreed packaging engineers and packaging testing equipment, including a hydraulic vibration table for transportation testing, a compression table and an incline impact sled. The company uses FEA (finite element analysis) capabilities to design and test customer products virtually. “With high-speed video, accelerometers, and full diagnostic and ISTA-certified report capabilities, FCA can provide our customers with tested and “pre-validated” packaging designs without needing a third-party testing lab or engineering group,” said Wilsted.

The Secret Sauce: Deep Customer Focus

However, the secret sauce of FCA’s continued success is its deep customer relationships. “The growth in the number of FCA manufacturing locations has been driven by our customers’ needs and requests to serve them in other locations as they grow,” Wilsted explained.

FCA’s ability to quickly establish new locations in response to customer needs is a core competitive advantage. “When customers choose FCA Packaging as their primary and usually sole provider for wood, steel, corrugated and hybrid material custom packaging,” he continued, “they tend to stay with FCA and ask us to grow with them. If they are expanding or moving to different sites, they ask that we put in new facilities to support them.”

Proximity to customers allows FCA to provide Just-in-Time (JIT) service, which saves on freight and provides other benefits as well. By ordering on a JIT basis, a manufacturer can generally limit its inventory, reduce the storage space required, and reduce the amount of handling required. Overall, a JIT approach promotes a leaner, more responsive approach to inventory management and production scheduling, which can lead to substantial cost savings and efficiency gains. However, it also requires precise planning and excellent supplier communication to avoid supply chain disruptions.

Changing Market Dynamics: Single Sourcing, Onshoring, Consolidation, Sustainability

Single sourcing is becoming increasingly attractive. As a strategy, it is often viewed positively regarding streamlined supply chain management, deeper relationships, more consistent quality, cost savings and faster response time. “As customers increasingly look for suppliers that can manage their custom packaging needs, including design, manufacturing, and management of custom packaging solutions and products on a national scale, FCA’s footprint and capabilities ultimately help us help our customers achieve their supply chain objectives cost-effectively across their own national networks,” stated Wilsted.

He commented that there is a gradual shift in more OEMs wanting providers who can serve them nationally with several different products and services across their network as they continue to adapt. “There is some consolidation as customers try to lower their costs and rationalize their supply chains,” he explained.

Wilsted also remarked on other recent trends, such as the onshoring of manufacturing and a greater shift toward customized solutions. “These trends are favorable for FCA’s business offering because of our national presence, our unique packaging design capabilities, and our procurement capabilities in a broad range of substrates,” he said. “Collectively, this allows us to provide our customers with custom-designed packaging at a competitive cost.”

Wilsted also touched on the increased importance of sustainability in the marketplace. “Our key suppliers are all part of the sustainability forestry initiative,” Wilsted said. “And aside from sourcing from sustainable sources, the company prides itself on converting those materials into sustainable products. “We design and build packaging out of reusable materials, and we help customers minimize waste.” Additionally, knockdown or collapsible design allows customers to ship packaging in higher volumes, reducing the number of trucks required. This results in environmental and cost savings.

One example of a commercialized collapsible packaging solution is its patented reusable C.U.B. (Collapsible Utility Box). The basic system consists of a pallet, an OSB collapsible collar and a lid, offered in a standard footprint of 24×24 with two height options. However, size, materials and other design aspects can be customized to meet customer needs. The C.U.B. system can be reused and repaired as needed, helping to reduce the use of new materials and waste generation.

Material Selection: Wood Remains an Important Differentiator

While FCA incorporates several materials into its packaging solutions, the company remains bullish on wood as a material of choice.

“The price tends to be much more competitive as an input material,” Wilsted admitted. He noted the ease of rapid prototyping, product revisions, and wood’s modest carbon footprint. Wood does not require large capital investments associated with other processes, such as injection molding plastic, for example, which might require modification at a later point.

“For these reasons, our customers tend to choose wood products as their primary packaging source, although FCA designs, manufactures, and manages steel returnable packaging, plastic lumber, and multiple material or hybrid packaging,” he said. “We learn from the customer what their cost, use, and shipping objectives are and then custom build the product around those requirements using the materials most applicable to the required results.

Not surprisingly, much of the company’s manufacturing equipment is focused on fabricating wood packaging. The company utilizes standard machinery for sawing, cutting, and assembly operations for custom packaging. “High-end” optimization saws are used for panel cutting, with programs for optimizing throughput and waste minimization.

FCA has an in-house customer web-based ordering system tied to its internal ERP systems. This allows the company to receive, process and monitor orders through customer-specific dashboards, if desired.

When Culture Meets Strategy

FCA combines strategy with culture to help power its success. “A winning strategy is critical in building a successful business focused on making our customers successful,” he said, “but in my opinion, without a good culture, the strategy will be less successful.

“As we have grown over the years, our goal has been to maintain that positive culture of a family and team-oriented environment, total commitment to the customer, passion for our work and our colleagues, and personal and professional growth,” he continued. “Our employees and teammates enjoy the work they do, they enjoy each other, and they have a passion for excellence and growing the business. When you can combine good culture with a sound strategy, great things happen, and we have certainly seen that in the history of FCA’s growth. Maintaining that culture has been paramount.”

That interplay between culture and strategy continues to be a winning recipe for FCA. “Our company has gone through many growth-related changes since inception and is delighted to work with our current and outstanding private equity partner, Wynnchurch Capital,” Wilsted reflected.

“Embracing change is part of our culture, and maintaining a focus on that culture and the customer-driven innovation, engineering, breadth of materials, and committed employees have been the recipe to our success,” he concluded. “When we serve our customers well, we continue to grow. We serve our customers well because we are innovative, committed, and have excellent employees who share that vision and culture.”