Every two years people from all over the forest products industry, especially the pallet sector, gather to see the latest technology in person at the East Coast Sawmill and Logging Equipment Exposition (EXPO RICHMOND). This show has become America’s leading trade show for the pallet sector. It is one of the few places where you can get up close and touch equipment and in many cases see it run.

EXPO Richmond this year was a good show according to exhibitors even though the numbers were down a bit from previous years. The event is one of the few places to see a wide variety of vendors serving the pallet market with live demonstrations. It was held on May 13-14th at the Richmond Raceway Complex in Richmond, Virginia. The event is put on by the Virginia Forest Products Association.

Our staff walked around and talk with various vendors and found the latest innovations being talked about by various suppliers for sawmill, grinding and pallet applications. This review covers some of what we found at EXPO Richmond.

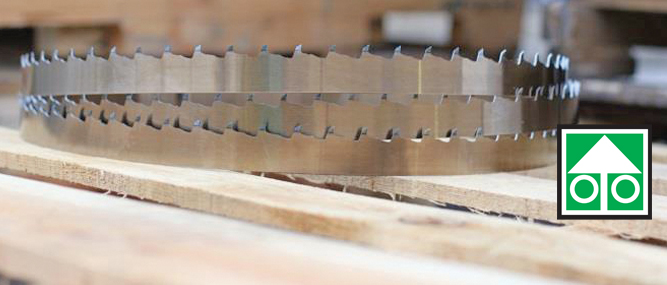

One of the neatest innovations I saw at the EXPO was the new Vortex® sawdust-removal bandsaw blade from Wood-Mizer, the only sawmill manufacturer to also produce blades. This innovative design is now available in the United States for sawmillers and pallet producers who need boards as free from excess sawdust as possible.

This blade is engineered to remove dust while sawing in order to minimize or eliminate the need for sawdust removal after the lumber is processed. This extremely unique blade profile has generated positive results in high-production pallet factory tests. It is ideal for those who have had sawdust issues involving frozen lumber in cold weather environments.

According to Wood-Mizer, pallet producer, Jeff Coomer of Indiana-based Coomer & Sons Sawmill, tested the blade and said, “The Vortex blade was getting 98 to 99% of the dust off, so it was impressive on how much dust it took off [compared to] a typical saw blade.”

For more information, visit www.woodmizer.com/vortex or call 800/522-5760.

Pallet Repair Systems (PRS) was there with Marc Perez of CAPE, the Spanish nailing machine manufacturer that earlier this year signed a deal to sell machines through PRS.

This is exciting news because it brings another major high-speed nailing company to the U.S. market. Product sales and support will be handled by PRS from its facility in Illinois.

If you want to see CAPE equipment run, a nailing line is currently in operation at the PRS showroom located in Jacksonville, Illinois.

Baker Products had on display its new sawmill and reverse flow edger system. This unit was featured on the cover of the May 2016 Pallet Enterprise. The idea is to reduce the labor needed in the edging part of the operation while improving yield. For more information, visit www.bakerproducts.net or call 800/548-6914.

Baker also showed off the new Wood Wizz, which is designed for wood workers. It allows operators to carry out contract surfacing and finishing for woodworkers. The Wood Wizz enables sawmillers to add value to slabs. This sturdy machine handles everything from slabs to burls to tabletops, including recycled timber. It can do 4-sided work and is much faster and cheaper than a CNC machine according to Clyde Reed of Baker.

The operator can adjust the speed when required to suit the job and produce a perfect finish without any tear, ridging or burn marks. It is powered by a variable speed 3-HP, 240 volt 3-phase motor. Baker is the representative for this product in the United States. For more information, visit www.woodwizz.com.

Robotics is starting to make some news in the pallet industry. Alliance Automation is working with Yaskawa to bring robotics to the pallet industry.

Both companies were there showcasing videos and talking about products under development for both pallet recyclers and manufacturers.

Robotics is starting to gain some traction because of the labor crunch, and the fact that robots always show up for work and don’t need health care coverage. Robots can be used for nailing, sorting and dismantling operations.

For more information, visit www.allianceautomation.com or call 419/238-2520.

As usual, Viking had a number of lines running at the EXPO including its new Express 403 and the Turbo 606. The Express 403 is a mid-line machine between the Champion and Turbo nailers. It can produce up to 1,200 pallets on a shift. Viking has showcased its video series highlighting success stories with its machines. The “Build your Legacy” series demonstrated how Viking equipment has helped fuel profits and productivity at some of the leading pallet companies in the country. Viking is currently looking for candidates for its next video series. For more information on any Viking line, visit www.vikingeng.com or call 763/571-2400.

Saw Service & Supply Inc. unveiled new safety products at the show, especially cut-resistant safety gloves.

It also offers safety glasses, ear plugs and muffs, hard hats, back supports, safety vests, masks, safety gloves and more. Saw Service offers a complete catalog of consumable products from saw blades to hand tools.

For more information, visit www.sawserviceandsupply.com or call 800/735-5604.

Bronco promoted its new 3-1 pallet nailing machine. This one man machine can produce a pallet every minute. It offers fast changeover and can be sized to handle large pallets.

It works well with recycled lumber and can produce either stringer or block pallets. It has a nail gun balancer and only requires minimal operating space.

For more information, visit www.broncosys.com or call 800/458-54672.

Pallet Machinery Group also operated a number of its equipment lines at the show. It showcased the R-35 vertical arbor gang saw from Storti. A number of these units are already in operation in North America. They are designed to replace bandsaws for increased feed in production and less downtime. It can also be used to produce cants requiring a much smaller footprint.

Pallet Machinery Group also showcased the AIT HY400, which is used for center splitting and is known for its high capacity. It has a production limit at 400 feet per minute. Although this system has been around for a number of years, a round table feed system was demonstrated. This innovation allows the outfeed to keep up with the production capacity of the saw.

A big debut was the TGS P 500 from Storti, a package saw that cuts from underneath instead of overhead like other systems. The reason for the underneath cutting is that it eliminates the need to set extra dunnage underneath the packs so that they don’t pinch, which can affect the accuracy of the cut. This unit can also be equipped with an auto band option to pre-band packs before the cut. This keeps everything tight and snug to increase accuracy.

For more information, visit www.palletmachinery.com or call 540/644-9220.

Go Fast Manufacturing has redone its line of end trim saws and resaws. The new double-end trim saw simply adjusts length of cut with the turn of a handle. It has a variable infeed chain speed and can be purchased with a precision laser guide.

Newly redesigned resaws have a quick air tension systems and decrease operator fatigue. It features a fully adjustable landing table and belt. For more information, visit www.gofastmfg.com or call 800/854-7439.

Macoser Inc. offers Stromab high speed crosscut solutions for cutting angles and defect cutting lumber. The WS1 can make 100 cuts per minute at

1/32" accuracy with a small footprint. It is ideal for defect cutting and sizing material for crates, pallets, laminates and finger jointed lumber. For more information, visit www.stromabusa.com or call 704/392-0110.

SII Dry Kilns promoted Thermo Vacuum technology, a technology from Europe it has started offering in the United States. This kiln technology is an eco-friendly process with no emissions. It dries faster than conventional driers with no deformations in the dried wood.

For more information, visit www.siidrykilns.com or call 800/545-6379.

Smart Products demonstrated a new conveyor to link its bandsaw dismantler to a trim saw. This system approach is ideal for those looking to use recycled lumber in their repair operations.

For more information, visit www.smartproductsinc.com or call 765/284-9545.

Noble Machinery showcased its power fed single end trim saw. It features four adjustable board stops

and a 10HP-3PG saw arbor motor. It doesn’t have any belts or pulleys to wear out or replace.

It end trims stringers and deck boards up to 2-1/2" thick. And it can produce up to 15,000 boards per eight hour shift. It is a heavy duty machine designed for production environments.

For more information, visit www.noblemachine.com or call 800/348-0703.

Air Flow Trailer Systems has upgraded its vent system to keep water out as the trailer moves down the road. Also, the company known for developing trailers to combat mold growth on pallets has added a model to allow power plugs in the rear of the trailer. Air flowing through the trailers helps dry and prevent mold growth while reducing lumber degradation and cracking in pallets. It is a proven method to combat mold growth developed by a pallet company for pallet suppliers. For more information, visit www.aftstrailers.com or call 262/677-9033.

A fully adjustable ergonomic pallet lifting attachment for the versatile line of vacuum tube lifters that lets one person effortlessly handle pallets was introduced by Universal Machinery Sales. The VT-PLA Pallet Lifting Attachment from Sort-Tecch lets one person lift and move pallets safely and easily, without bending and stretching, by using the VT-Series tube lifter.

Featuring a quick-release mount, the attachment can be easily swapped out with the full range of vacuum pads that are available to handle boxes, pails, and a wide variety of other items.

Fully adjustable for handling standard 48 inch (1.2 m) sq. and other pallets, the VT-PLA Pallet Lifting Attachment is made of durable extruded aluminum and replaces a manipulator at a fraction of the cost. Providing a 100% duty cycle and a special valve which creates an air tight seal when the load is attached, this lifter operates with an overhead crane system.

For more details, call Mona Tracy at Universal Machinery at 855-298-8890.

This was a review of what we saw at EXPO Richmond. If we missed out on some news you made, please let us know and we will mention it in a future issue.

You can email chailleb@gmail.com to update on us developments that we may have missed, or call 804-550-0323. We hope to see you again in 2018!