Compressed air is used every day in a pallet mill to power nailers, pneumatic equipment, automation equipment, conveyors controls and actuators. Energy cost to power compressed air systems may exceed 10% of your annual energy bill. Improving the energy efficiency of the compressed air system will have a direct impact on your bottom line.

Electric utility incentive programs can help improve the cost effectiveness of several of the top ten compressed air savings suggestions.

Compressed Air System Basics

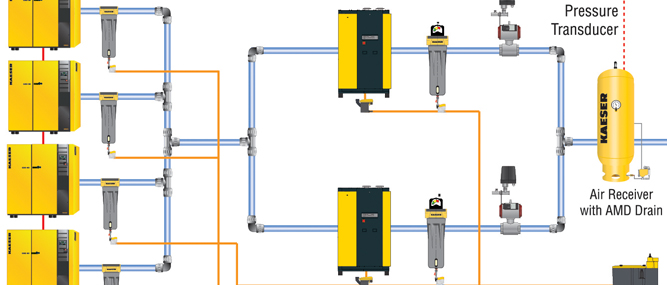

Many utilities across the country offer compressed air incentive and custom incentive programs that help pay for items such as air compressors, variable frequency drives, air receivers, dryers, no-loss drains, high-efficiency air nozzles, low pressure drop filters, ultrasonic leak detection and compressed air evaluations. Kaeser Compressors, Inc., http://us.kaeser.com/, provided the Optimized Compressed Air System Schematic shown in Figure 1. This diagram is useful in identifying many of the incentive program items. A compressed air system is composed of a compressor, controls, tanks and a highway of pipes throughout your facility.

Who Offers Compressed Air Incentives?

Many utilities such as ComEd, https://www.comEd.com/Bizincentives, offer compressed air and custom incentive programs. ComEd’s stated goal for its Comprehensive Compressed Air Study Program is to “identify opportunities to improve the efficiency of your facility’s compressed air system and reduce energy costs without adversely affecting system operations,” http://goo.gl/Aw8osa.

An excellent resource for locating energy incentive and rebate programs is DSIRE (Database of State Incentives for Renewables and Efficiency), www.dsireusa.org.

What Equipment and Services Are Eligible for an Incentive Payment?

Each electric utility that provides compressed air or custom incentive programs has a different list of equipment or services that are eligible for its specific programs. Common items that are included in these programs are air compressors, variable frequency drives, air receivers, dryers, no-loss drains, high-efficiency air nozzles and low pressure drop filters. Free or subsidized services may include ultrasonic leak detection audits and compressed air system evaluations.

Evan Sparer, systems engineer at Ingersoll Rand in Richmond, Virginia (www.ingersollrandproducts.com), said that on a recent installation his company was able to completely stabilize plant air pressure and shut off two less efficient compressors, saving the customer $35,000 per year in energy. Sparer continued, “There is a lot of opportunity in replacing wasteful timed solenoid drain valves with Pneumatic no air loss drains.”

How Can the Incentive Payments Be Received?

The procedure to receive the incentive payment varies with each utility and may include an initial compressed air system evaluation, leak detection and sealing, and pre-approval using a worksheet. For example, look at this ComEd worksheet online at http://goo.gl/KB1hy2.

Be sure to read all of the small print and pay attention to any incentive caps, requirements to use utility approved contractors, and deadlines to make application for the incentives.

Forest Industry Success Story

It is reported that Columbia Forest Products in Newport, Vermont saw an estimated lifetime customer savings of $540,000. Gerry Mongeon at Air Compressor Engineering (www.aircompressoreng.com), a full-line master distributor for Ingersoll Rand since 1960, said that his team worked with Efficiency Vermont, www.efficiencyvermont.com, to obtain the incentive payments. You can read the whole story at http://goo.gl/V6PJg5.

Columbia Forest Products had an air compressor that failed. When one of their two main air compressors failed, Aaryn French, plant engineer at Columbia Forest, then sought the advice of Lenny Mongeon at Air Compressor Engineering in Hinesburg, Vermont. Together they contacted Efficiency Vermont to conduct an energy use assessment of the factory.

According to the Efficiency Vermont success story, “During the assessment, numerous air leaks that put a strain on the compressed air equipment were identified and repaired. This leak correction reduced the demand for compressed air, and as a result, the replacement air compressors could be smaller and designed to operate more efficiently.”

The success story reports an energy efficiency investment payback (including incentives) of five months and an estimated first year utility bill savings of $54,000.

Top Ten Steps to Compressed Air Savings

1. Turn It Off

2. Fix Existing Leaks

3. Prevent New Leaks

4. Reduce Pressure

5. Check Drains

6. Review Piping Infrastructure. Many systems are not optimized.

7. Change Filters Systematically. Not every once in a while.

8. Recover Heat. Compressing air generates heat – reuse it!

9. Emphasize Proper Maintenance. Ignoring maintenance costs more.

10. Identify & Eliminate Inappropriate uses of compressed air.

(Source: The Compressed Air & Gas Institute)

Resources

• DSIRE — www.dsireusa.org

• “Compressed Air Best Practices” magazine Energy Incentives — http://www.airbestpractices.com/energy-incentives

• Ingersoll Rand white paper on the effects of system pressure on compressed air system energy consumption — http://goo.gl/bl7MYs

• Compressed Air Challenge — www.compressedairchallenge.org

• Compressed Air & Gas Institute — www.cagi.org.