The same scanning and inspection system that has made it easier to manage pallet quality for European retail pools is coming to North America. Alliance Automation has entered into an exclusive partnership with IVISYS to commercialize its 2-D pallet inspection machine and AI-assisted analysis software.

Although Alliance Automation had developed its own pallet inspection machine, the iPallet, the company was blown away by the capabilities of IVISYS, especially its software.

Doug Wenninger, president of Alliance Automation, explained, “Their inspection process and their software capabilities were phenomenal. It was the best that I have seen. They were way further advanced than our iPallet system.” He added, “IVISYS didn’t set out to design a machine for the pallet industry; they set out to design a machine for the warehouse/distribution center sector.”

The IVISYS system has been extensively used in Europe to manage a variety of pallet pools to monitor quality, grade pallets and manage control standards. Alliance Automation has signed an exclusive contract to sell IVISYS inspection systems and software in North America for the pallet industry. Also, Alliance Automation will be the exclusive integrator providing service and installation in North America for the distribution center and warehouse market. The first white-wood inspection system is set to be installed early next year at a Canadian pallet recycler.

Alliance Automation pursued this relationship after a white-wood customer inquired about integration services involving the IVISYS system.

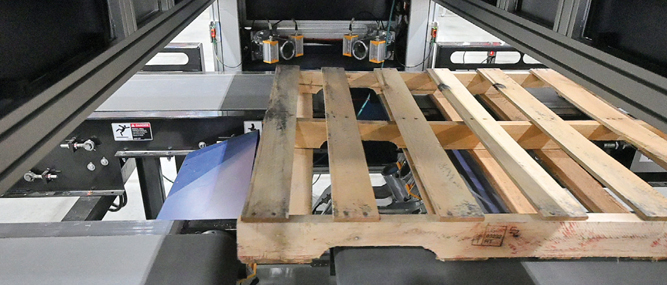

A key to the IVISYS approach is the artificial intelligence (AI) software behind the analysis. PALLETAI functions like a human-like inspector, thoroughly examining the pallet for defects, conforming to quality standards, size, etc. The system runs no less than 26 neural networks and 2D cameras are combined to achieve maximum effect.

IVISYS stated, “Since the sixteen cameras combined generate almost 200 images per pallet, no area is left unseen, and the best resolution is measured in sub millimeters. Everything measured is then handed over to the customer who configures in detail how they want their sorting and which criteria are the most important.”

Wenninger admitted, “I was amazed at the speed of analysis done by the IVISYS software. I was impressed by the combination of the camera, scanning methods and software. “Alliance Automation guarantees throughput of at least 600 pallets per hour, although that figure could reach much higher as the system is optimized for various supply chains. Wenninger explained, “The system has an AI component built into it. So, as the system sees new things, it becomes smarter and better at inspecting pallets.”

Beyond pallet quality or damaged parts, the system can also look for other details. IVISYS claims, “AI similarly is perfect for detecting mold or discoloration through pattern recognition.”

PALLETAI can identify pallet size, color, condition, specific damage to individual components, compliance with established standards, etc. See Sidebar 1 for an entire list of what the system can inspect and sort for.

The IVISYS system is ideal for white-wood recyclers, rental companies at depots and pallet users at warehouses and major distribution centers. Wenninger stated, “A number of these systems have already been sold in the United States, and they are becoming more popular with highly automated distribution centers.” He said that pallet failures causing jams are a major problem for Automated Storage and Retrieval Systems (ASRS) leading to significant downtime. Better pallet inspection will even help companies that use slave pallets in these environments. Also, distribution centers can improve control over their own white-wood pallet assets, keeping more of the premium pallets for their own use.

The pallet inspection process helps recyclers by improving the grading and sorting of incoming loads and measuring what is actually in each trailer. The data captured by this system is invaluable when it comes to making smart pallet decisions. Wenninger suggested, “The IVISYS system views your data – as many data points as you want to collect. Now, these plants will know exactly what they are getting each load with data to back up their analysis.”

IVISYS commented, “Our software can track loads from customers, save data on all defects and create reports that can be used for discussions as well as pricing. With the data packages it is also possible to get a detailed view of all pallets flowing through the facility on a component level basis.”

Although there is no typical configuration, a common layout of a system would include the following elements: a tipper, a singulation area, inspection system, sorting area and possibly conveyors to other parts of the line or stackers.

For more information on the new IVISYS and Alliance Automation relationship, call (419) 238-2520 or visit https://ivisys.com or https://allianceautomation.com/.

Sidebar 1

The IVISYS Inspection System Can Scan, Analyze and Sort for the Following:

• Length and width

• Length and width individual board

• Material loss

• Gaps between boards

• Protruding material or nails

• Component alignment

• Cracks on boards or stringers

• Skewness and planarity

• Discoloration and foreign material

• Stamps and marks

• Plastic wrap/threads

• Perimeter blocks and stringers

• Missing component

• Broken or damaged blocks

• Mold and discoloration