One of the most trusted names and longest standing suppliers in the U.S. pallet sector, Viking Engineering & Development is on the move. A leading supplier of stringer-pallet nailing machines is moving into a new, larger facility to better service customers and meet equipment demand. Viking has launched a new online training service called Viking University. And its new high-speed nailing machine, the Voyager, has impressed Savanna Pallets with its production and performance. Viking recently highlighted the capabilities of the Champion QC306 at EXPO Richmond with its ability to process recycled components. Find out more about these developments in this review of the latest Viking news.

Kurt Larsen, president of Viking Engineering & Development, stated, “Viking is on the move, developing new machines and support solutions with a constant focus on outstanding service, to better help our customers keep ahead of changing times. No matter where your organization is, or where you want to take it, Viking is the partner for you.”

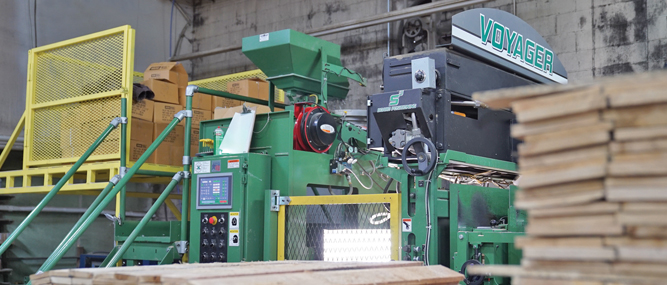

Success of the Voyager – First Machine Running So Well, Its Owner Bought a Second One

Viking’s latest machine is putting up some impressive numbers on its maiden voyage, consistently producing more than 2,400 GMA pallets in an eight-hour shift. The Voyager features a redesigned hopper fed nail delivery system and dual board hoppers. These upgrades reduce operator activity, improve ergonomics and help workers keep up with the increased speed of the machine.

The first Voyager was installed at Savanna Pallets Inc. in July 2021. Chad Raushel, operations manager for Savanna Pallets Inc., recalled, “Viking had showed us the new machine they were developing. Given Viking’s proximity to our plant and how many pallets we want to produce, they suggested the Voyager would be a good fit. We ran it for a week, and Viking sent its engineering team to evaluate and make some adjustments. That process continued for a while until we settled into a regular production routine. Now, we are getting 2,200-2,400 pallets in a typical shift, depending on pallet type. We have even hit 2,900 in a shift, that’s our record to this point.”

Chad Raushel is part of the third generation of his family to work in Savanna Pallets. His father Larry is one of four brothers who own the company today and are in the process of transitioning leadership over to the next generation.

Getting the first of any machine could be a bit risky. Chad explained, “That’s always in the back of your mind. But what gave us the confidence is the close proximity of Viking and its excellent reputation. Its headquarters is only two hours away. We have a ton of experience working with them since we run four Viking Turbos. We know Kurt and his team provide outstanding support. That made the decision to invest in the Voyager a lot easier.”

While it can produce a wide variety of pallet sizes, Savanna Pallets primarily uses the Voyager to run three stringer to four stringer GMAs. One hundred percent of the wood comes from the company’s sawmill. Savanna Pallets has not had to change anything when it comes to lumber prep or cutting to supply the Voyager. It runs the exact same type of material that has worked in the Turbos for years, both hardwood and softwood lumber.

Over the last couple of years, Savanna Pallets has grown from 45,000 to 50,000 pallets per week to around 65,000 pallets per week today. Due to the company’s growth, the current production capacity of the Voyager is spoken for.

Chad stated, “The Voyager took a lot of great things about the Turbo and improved upon it. We have found the Voyager to be a significant upgrade and have already put in an order for our second machine. It should get here in the fall and will replace an older Turbo.”

Changeover time is cut in half. FMS tooling now comes standard on all stringer rails and nail tracks have been replaced with air assisted, flexible tubing. S3 Board Positioning™ allows for dropping boards, instead of sheering, eliminating shear jams at the hopper.

Doug Raushel, co-owner of Savanna Pallets, said, “No inspection is needed on the Voyager, S3 Board Positioning™ works so well that you can’t really build a bad pallet on this machine.”

Production depends on a variety of factors. Chad explained, “In order to hit that peak figure (2,900), the biggest factor is lumber quality. If you are not having to stop because of a broken or short board, then you can get much better production.”

The biggest bonus of the Voyager design is the dual hopper. Chad said, “The dual hopper is a big deal. It certainly reduces some wear and tear on the operator. The dual hopper just makes the machine easier to operate.”

Chad added, “The electronics on the Voyager are much more advanced than the Turbo. This makes changeovers easier and faster…Changing from a three to four stringer design is faster than a Turbo. It takes only minutes. The learning curve is less on a Voyager. The experience level the operators needs to make efficient changeover has improved quite a bit. A new operator can quickly get up to speed on the machine due to the intuitive design of the controls.”

Savanna Pallets currently runs four Turbos, and the company has found success having older Turbos upgraded using the Viking Turbo 505 Silver Upgrade Kit.

Chad said, “Some of our Turbos were quite a bit older. We were approached by Viking about the benefits of the upgrade kit, and so we decided to upgrade two machines. The result has been a 10-15% production boost, and the revamped controls are more user friendly.”

The upgrade process is pretty easy and non-invasive. Viking technicians come onsite to perform the upgrade. It usually takes a day or two. Chad stated, “The turnaround was really quick, and Viking’s technician took care of everything.”

After sales support is critical with pallet machinery, and Chad explained, “Viking’s support with the Turbos and the Voyager has been fantastic. They are very knowledgeable and quick to reply and always have parts on hand. We are using Viking nails, and despite industry shortages. Viking has kept us supplied.”

Running Recycled Lumber Like a Champ

Richard Berry of Berry Pallets in Waseca, Minnesota has been a big fan of Viking Champion nailers for a long time. He declared, “A Champ will nail anything you throw on it. I have been running recycled boards on it since day one.”

In all, Berry Pallets runs two Champion QC306 machines and a Turbo 505 to produce a wide variety of new, combo and recycled pallets. Berry bought his first Viking in June of 1995. The thing that impressed him the most was its accuracy. Berry noted, “My first Champion was very accurate, even when it comes to using recycled boards and stringer. You can run 100% recycled lumber. It does extremely well with combos. We also run a lot of low-grade pine, waney boards.”

“When you run 100% recycled, you have to run the boards with the nail heads down to get the best results. Overall, the Champion does a good job putting the nails into the recycled lumber.”

Having the right nail is very important when using recycled lumber. Screw shank nails with a blunt diamond point work best. The reason is that no-point is hard to drive into the wood. Berry procures these nails from Viking as well as other sources.

The secret is to prep the recycled stringers to produce more uniformity. Berry explained, “I must be the only guy out there doing this. But PRS has a Stringer Sizer Machine. And we run all of our recycled stringers through it. This machine pushes any nail stubble in and then planes it down to the right size. We set our machine at 3.5 inches. It may shave off an eighth of an inch. This leads to fairly uniform stringer height.”

Berry admitted, “I don’t have any issues using recycled stringers in a Champion.”

When it comes to deck boards, Berry said you don’t need to size them. Instead, his workers sort boards at the trim saw. Berry said, “Have to match them up to size. You want no more than a 1/16 of an inch difference on the boards used on a pallet.”

Currently, Berry Pallet uses an Alliance Automation Robot Dismantler to take apart pallets. He keeps a pallet near the robot just for material with nail stubble or residue on the board. Those boards will then be run through a Heartland bandsaw to cleaning up the boards.

“When you put the boards out next to the nailing machine, you want the boards to be ready to go. You don’t want any problem boards that the operator has to sort,” advised Berry.

The Champion’s versatility is the reason that Berry Pallets produce odd-sizes and harder to produce pallets on this machine.

Depending on the ability of the operator and the pallet spec produced, a great production is 60 pallets per hour with recycled lumber. That equates to about 450+ pallets in a shift. Berry said, “It’s a little more work to run recycled lumber in the machine. You are not going to produce 500-550 pallets like some claim they can on a Champion with all new boards.”

But when you are looking for a one-operator machine with versatility, Berry declared,

“There’s nothing out there quite like a Champ…Viking may cost you more, but I have never gone wrong buying quality. Never. You buy quality equipment; you are going to have quality results.”

Unmatched Service, Viking Gives Old Champs New Life

Many pallet customers choose Viking because of its reputation for outstanding customer service and support. Viking staffs a full-time call center where technicians are available to help diagnose and trouble shoot machine issues, order parts and provide operation tips. In situations where an on-site visit is needed, Viking has a dedicated team of traveling service technicians available to come to your facility to assist with repairs and maintenance as well as machine upgrades and installations.

Viking recently assisted CR Brokers with a used Champion it acquired from a 3rd party and were having difficulty getting it up and running. After calling Viking service, CR Brokers was operational in less than two weeks. “I am very impressed with Viking’s service throughout this process. We only spoke a week and a half ago to get the ball rolling, and now it’s fully updated and operational. That is just unbelievable timing,” said Ryan Emenecker of C&R Brokers.

New Support Resources, Introducing Viking University

Viking has also improved its educational resources for customers. The company has launched Viking University, an online portal that is free to customers and features maintenance/training videos and a networking forum for Viking customers. The aim of the portal is to help customers get the most out of their machines and better train personnel.

Currently, the portal has Turbo 505 videos and Champion videos with additional videos being developed and added regularly. Viking’s goal is to grow and develop the program based on customer feedback and requests. Viking University is currently hosted through the Google Classroom platform, you will need a google account to access, which is free to setup. To sign up for Viking University, visit https://www.vikingeng.com/viking-university-enrollment.

Viking Moves to a New, Larger Facility

Later this year, Viking is moving into a 120,000 sq feet state-of-the-art manufacturing facility in Blaine, Minnesota. This move triples the size of the manufacturing space for increased production of new equipment and refurbishing of older Viking machines. Every inch of the new facility was intentionally designed for pallet equipment manufacturing. The new facility includes a 100% climate-controlled manufacturing floor, upgraded refurbishment steam and paint booths, in addition to dedicated space for protype development and testing. “The new facility will be an inspiring collaboration center for Viking employees to design, manufacture and build Next Level solutions for our customers,” said Kurt Larsen.

As Viking invests in its facilities, this will help the company grow and attract even more talent to better service customers and the industry.