Running a successful pallet company comes down to one word – vision. Anybody can make a pallet. What is much harder is to make pallets efficiently, provide top-notch customer service and develop an environment where people want to show up for work. Fox Valley Wood Products of Kaukauna, Wisconsin and Savanna Pallets of McGregor, Minnesota have figured out how to achieve these goals. These two companies also credit machinery from Viking Engineering & Development as a contributor to their success.

Jeff Van Zeeland, vice president of sales for Fox Valley, explained, “Our vision is to make the lives of our employees better. If we do that, they will ensure that our customers are taken care of, and Viking equipment allows us to hit production targets while reducing strain on our workforce.”

Thanks to its growth and success story, the Wisconsin Manufacturers & Commerce (WMC) recently recognized Fox Valley Wood Products as the Wisconsin Manufacturer of the Year for the small business category. Dale Van Zeeland, one of the owners of Fox Valley, commented, “Our company was recognized for our sustainability, manufacturing efficiency, employee engagement and financial stability. These are the primary criteria used by the WMC in its analysis. We are very proud of the hard work by all of our team members to receive this honor.”

Just like Fox Valley, Savanna Pallets has marked its success by sales growth. The company has grown 20-30% over the last 3-4 years and now produces about 80 truck loads per week. Al Raushel, vice president of Savanna Pallets, said, “We are always trying to reinvest in the company and find new ways to make the job easier… That’s why we are automating as much as we can in our pallet and sawmill operations.”

Both companies have pointed to the reliability of the Viking machinery and service as critical to ensuring efficient production. Doug Raushel, general manager of Savanna Pallets stated, “Viking machinery just runs well, and the Viking service is second to none. It truly is the best service we have received from any vendor in the industry.”

Doug added, “I believe the Viking 505 is still the best machine out there for the money when you consider production efficiency, manpower requirements, reliability and machinery cost.”

Let’s look into what has made this relationship so successful for each of the top pallet manufacturers.

Fox Valley’s Viking Story

Fox Valley has achieved top 2% production in its Viking nailing lines according to Travis Van Zeeland, vice president of manufacturing. He said, “We have really good operators who have been with us 10-20 years. We used lift tables to reduce strain as workers load lumber, and Dale ensures that we obtain good quality lumber to run through the machines.”

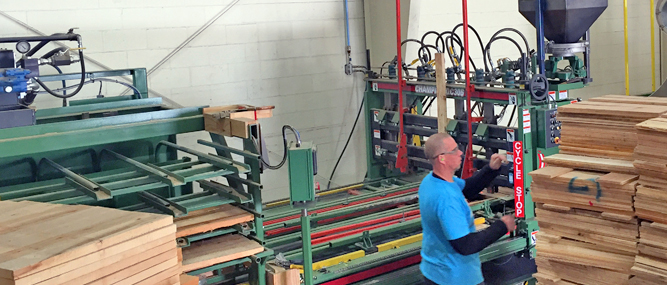

Currently, Fox Valley runs one Turbo and two Champion nailers. Fox Valley can produce 225-300 pallets per hour on its Turbo and 55-80 pallets per hour on its Champions.

The company recently upgraded adding a new Turbo 505 and a new Viking Champion. Travis explained, “We try to upgrade our machines every 7-8 years to keep up with changes in the technology. Our newer model Turbo 505 can produce 30-40 more pallets per hour and is easier to maintain and run.”

Another key to better performance is a better nail. Dale explained, “We like to use mostly Viking nails because they run well in the machine and are good quality. Viking nails are straight, consistent, and we can get them for a good price too.”

Dale pointed to the customer support offered by Viking’s nail department. He said, “Joan at Viking takes great care of us and makes sure that we get whatever we need.”

The Turbo produces primarily 48×40 pallets while the Champions produce a lot of different sizes ranging from 24×24 to 60×66.

Savanna Pallet’s Viking Story

The company bought its first Uni-matic in 1991 and has run a Champion nailer in the past. Today, it operates 4 Turbo 505 machines in addition to a Storti Flex system, a Storti T-Flex and a LZ nailing system.

When it comes to training, Doug said that the Viking machines are easier to train new workers on than some of the other machines they have used or seen throughout the years.

Savanna Pallets produces 50,000 pallets per week. It routinely manufactures 1,800 to 2000 pallets per shift per machine. Since Viking is located so close to the Savanna plants, it provides fast support on parts, nails and anything else required.

Doug admitted, “Kurt Larsen, the CEO of Viking, will call us up from time to time just to see how we are doing and make sure that we are getting top-notch service. Most other vendors aren’t as proactive as this.”

Kurt Larsen commented about the relationship between Viking and the two companies featured in this article. He said, “Both Fox Valley and Savanna Pallets are well run productive family organizations whose success primarily stems from their leadership along with a highly efficient workforce and equipment. Viking Engineering has had a special relationship for many years with both companies. We truly believe that our partnership has helped Viking make improvements in multiple areas while both firms continue to offer valuable advice and assistance. We are extremely fortunate to be able to work with partners such as Fox Valley and Savanna Pallets.”

Better Pallets & Customer Service Start with Closely Controlled Lumber Operations

Both Fox Valley and Savanna Pallets control a critical aspect of their supply chain. They operate sawing facilities to ensure proper lumber quality and on-time delivery.

Doug explained, “It takes a lot of lumber to feed 4-5 nailing machines. Having our own sawmill allows us to turn on a dime to produce whatever the customer needs. We cut close to one million board feet per week from our four sawmill lines.”

Savanna Pallets uses at least 80% of the cut stock it produces and sells the rest to other pallet companies. Doug said, “We cut whatever is available. Right now, we are cutting a lot of pine, some aspen and some hardwood.”

One sawmill line produces just deck boards. Two other lines produce cants, stringers and four quarter boards. The company also operates a stand-alone sawmill in Remer, Minnesota. It focuses primarily on deck boards.

Fox Valley has found running its own lumber processing facility has improved its ability to respond to changing customer needs. Travis Van Zeeland suggested, “Putting up a mill across the road has been a huge advantage. It has improved our timely response to customer requests and sped up our delivery times.”

In addition, the company has achieved greater efficiencies. Travis explained, “We are getting probably twice the footage as we used to with probably one to two fewer workers.”

Dale said that Fox Valley’s sawmill processes mostly 4/4, 5/4 and 6/4 lumber. This facility center splits the material, cuts it to length and produces what is needed for pallet production. Lumber goes from a Newman KM-16 saw designed to trim lumber into multiple lengths. Material is conveyed to an unscrambler and then is processed through a McDonough band mill. Cut boards go to an M2L stacker for efficient stacking.

Fox Valley has also put in a Go-Fast horizontal bandsaw for processing 4/4 material. It goes through a McDonough band mill and is then split the other way so that they produce whatever is needed on the other end.

Jeff added, “The one thing that is unique about that facility is its versatility. We can cut very short boards or long boards depending on what is required. All we have to do is move a few pieces of equipment. We are always looking for ways to do it better, but we keep coming back to this setup.”

Rewarding People Leads to Better Pallets

Both Fox Valley and Savanna Pallets credit their people for making things happen. Dale admitted, “We treat our people well and give good benefits.” Fox Valley offers safety and attendance bonuses in the form of gift cards. And the company has profit sharing where employees can earn up to 15% of their annual salary. Depending on the season, Fox Valley employs 35-36 people.

Likewise, Savanna Pallets is committed to its people. “With around 150 employees over 3 locations, we have focused our efforts on providing consistent increases in wages and benefits, improvements in working conditions through continual improvements and upgrades in equipment such as the new Turbo 505 purchase and most importantly by developing our existing employees technical skills so they can move on to higher paying and rewarding positions within the company.

Over the past several years we have made significant advances in our operation by employing our own Master Electrician and automation control specialist in addition to the 5 millwrights on staff. “We are now designing and building a lot of our own processing lines which we can control through PLC programs which we develop. Most recently we have added a robotic arm with an attached nailer. We are looking to improve worker productivity and safety in the production of non-standard and specialty pallets.

The longevity of its staff makes a difference. Al said, “I have been in the pallet business since 1993. And we still have employees that have been here longer than me. So, we have several employees who have been with us almost 30 years.”

One way the company shows its commitment is by investing in new equipment. Al pointed to the four new forklifts the company buys regularly to keep them functioning well. Savanna Pallets uses Nissan forklifts with enclosed cabs because Minnesota has real tough winters. The company tries to automate where it can. It has even experimented with a robot to produce over-sized pallets. Doug said, “The robot nails boards in a jig. We are trying it to save labor and prevent worker fatigue. So far, so good.”

Disposing of wood residuals remains a constant challenge. Because we go from tree to finished pallet at the same location we generate a tremendous amount of wood residue. Utilizing three Rotochopper grinders and multiple chippers, we produce 75 semi-loads of wood residue per week. To move all of this material we are in the colored mulch market, playground surface material, animal bedding and industrial bio-mass fuel for large electrical generation facilities.

Both companies are also family businesses where the family members are hands on, daily guiding the operations. At Fox Valley, Jeff works with his uncle Dale and his son, Travis. They share core management duties. Dale manages the lumber procurement. Travis runs the production and manages the schedule. And Jeff oversees inside sales and customer orders.

Savanna Pallets was started in 1966 by Frank Raushel and is now owned and operated by his 4 sons, Larry, Doug, Al and Andrew. Although each owner has their area of expertise, the four brothers share in the decision-making process equally. “The organizational structure is somewhat unique but it works well for us.

The Raushel brothers take a hands-on approach to management. Doug said, “I can run any machine in our plant, and take it apart and put it back together.”

While these two businesses are different, they share some common attributes – family leadership, control of their lumber supply chain and reliance on Viking for dependable pallet production. How can the secret to their success help you in the future? Find out more about Viking and its focus and vision on the sidebar on this page.

Interview with Kurt Larsen, CEO of Viking

The Pallet Enterprise spoke with Kurt Larsen, the CEO of Viking Engineering & Development, to delve into the company’s vision, technology and customer service approach.

What makes Viking such a strong partner when it comes to ensuring pallet production keeps humming?

Larsen: Viking's corporate values and culture are driven by our commitment to excellence in customer service. In short, we define it as doing the right thing for the customer. It starts with dedicated people that believe in serving our customers and continually improving critical customer service areas such as faster deliveries, increasing machine efficiency and reliability, increasing the value of our products and services, maximizing customer uptime and ultimately increasing customer rate of return with Viking offerings.

How has Viking evolved over the last few years? What is your focus for the future? Any technology focus or new developments?

Larsen: In my 5 years at Viking Engineering, I have witnessed how strong values can galvanize a company together during strong economic headwinds and how employees can truly drive purpose, vision, and impact.

One of Viking Engineering’s initiatives is for new product development and innovation. Currently, Viking is developing a new pallet nailing machine called Voyager which has improved pallet manufacturing productivity along with dual hoppers and is expected to launch in early 2021. We are including our online Smart Data system in the Voyager to give our customers another tool to improve their manufacturing efficiencies. In addition, we are evaluating the incorporation of cluster nailing and laser technology for scanning and sensing into future pallet manufacturing machines. Our successful approach to integrating technology into pallet manufacturing machines utilizes stitch nailing technology, which has been developed over many years with North American customer input based upon their challenges with labor and material variability.

Currently, we are celebrating 25 years of production of our Turbo 505 model which has been dramatically improved since its inception. Customers have stated that they have received a 10-20% immediate production increase from purchasing a new Turbo 505 versus their older 505 model.

We also understand the importance of our customers to be able to upgrade their existing machines to current technology and have made an intentional effort to improve our retrofit program. Finally, Viking has developed a product utilizing a patent pending laser guided fastening system for the bedding industry and anticipates using the technology on future pallet nailing machines.

Your customers spoke about the strength of Vikings people. What is the culture that Viking has sought to develop? As the top leader, what do you want customers to say about your company?

Larsen: Ultimately, Viking employees want our customers to succeed. Their success is Viking’s success. I would want our customers to view Viking as a trusted partner that listens, cares, innovates, and is always responsive to solving customer problems and needs.