Laurinburg, NORTH CAROLINA – When a competitor says visiting one of your plant’s is like visiting Disney World, you know you must be doing something right. That’s the reality for Jeff Edwards and his team at Edwards Wood Products. On a road trip last year, the CEO of a major pallet company, gave the Edwards facility that specific compliment.

Edwards Wood Products has grown from a small pallet shop started in an abandoned chicken house in 1969 to a major force in the pallet industry. Today, it produces about 135,000 pallets per week and consumes 350 loads of wood per day. The Edwards Wood Products (EWP) network includes three scragg mills, two chip mills, five hardwood grade mills and the new pine mill in addition to drying facilities and multiple pallet manufacturing plants spread across North Carolina and South Carolina.

Last year, EWP celebrated its 50th anniversary with a huge party for customers, employees and suppliers. Jeff Edwards, the president and CEO and son of the founder, reflected, “Our success goes back to our core values – doing what we say we are going to do, offering on-time delivery, keeping plenty of inventory on hand and focusing on quality and service.”

Edwards remembered, “In the early stages my dad’s philosophy was whoever did the best job at making pallet lumber in the most cost-effective manner was going to have the upper hand. Thus, we started off with scragg mills back in the early 80s. We were buying small, low-grade logs and turning them into pallet lumber. And that was kind of what gave us the boost we needed to grow.”

Lumber remains at the heart of EWP as the company is perfecting its latest sawmill development at a site in Laurinburg, North Carolina. EWP acquired an existing metal manufacturing plant on 100 acres adjacent to its existing scragg mill and chipping operation and retrofitted the facility. Edwards explained, “There were several reasons for building the new sawmill operation in Laurinburg. One was to produce enough pine cut stock to eliminate the need for sourcing from outside suppliers, while also adding enough capacity to grow the pallet sales side of our company. We also wanted to have the flexibility to run soft hardwoods for industrial timbers and ties. The mill is also designed for producing a high volume of pine dimension lumber if we wanted to move in that direction in the future, so we designed the mill to do a lot of different things.”

Construction went quickly at the new Laurinburg mill; it took about a year from the time the crews broke ground to the first day of operation in 2019. This sawmill provides EWP the ability to process pine cut stock with logs coming from the 30,000 acres of mostly pine plantation owned by the company as well as a good mix of log supply from local wood dealers.

Edwards believes it is important for a new pallet manufacturer to control the raw material supply chain as much as possible. He said, “It enables you to control the cost while assuring yourself a consistent supply of material. We may go a little overboard with the amount of stumpage (standing timber) we keep bought ahead, as well as the large inventory of roundwood we keep on our mill yards ahead of production. We’re serious about maintaining an uninterrupted supply of products to our customers.”

Few pallet companies process or procure all of their material from company owned sources. But EWP has developed a network of loggers to harvest material from third-party sources as well as EWP forests.

Controlling raw material costs is a major driver for EWP’s success. The company was founded by Carroll Edwards, a truck driver who built a large, vertically integrated pallet company and sawmill from nothing. Carroll’s success made him an industry legend before he passed away in 2008. Much of the company’s success also springs from the ingenuity and planning of Carroll’s son, Jeff, who guides the operations today.

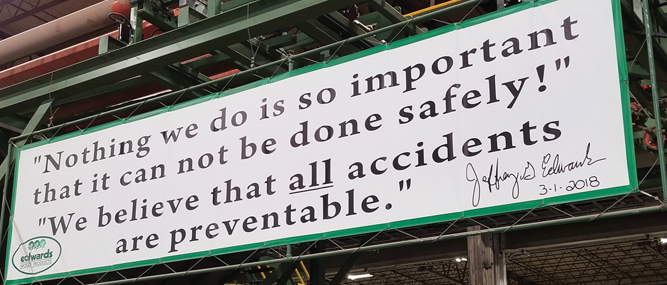

Edwards stated, “We try to do things right… We focus on running safe facilities. All of our plants are Safety and Health Achievement Recognition Program (SHARP)-certified by OSHA. It is tough to get in that program and to stay in. Our first plant to get SHARP certified was 13 years ago.”

EWP has the first sawmill in the state of North Carolina to attain the SHARP status. Edwards commented, “I believe we, as owners and managers of our companies, have an obligation to provide a safe work environment for our employees. It takes a lot of effort and commitment from every team member to support this, but nothing we do is more important.”

The size of the EWP operations is massive with much of the facilities under roof. This allows the company to supply even the largest accounts with ease.

In-depth Look at the New Hybrid Mill

EWP converted an existing 300,000 sq. foot facility, into its new Laurinburg sawmill. A small portion of the building was demolished, due to needing more height for equipment, while new space was added for the log merchandizing line. The process begins with a Nicholson A8 debarker. Tree length logs are debarked and then travel through a dual zone log scanning system provided by Porter Engineering. The scanning solution is then passed off to a Timber Automation Log Pro 5 Saw Bucking Station. Cut to length logs then pass through an MDI metal detector before heading to the primary breakdown.

Logs enter a Cone-Omega Tru-Position line, that includes a linear motion log turner for correct log positioning. Logs go through multiple Porter Engineering scans before entering a canter twin section featuring the Omega slant canter and McDonough twin band.

Edwards said, “We used Porter Engineering out of Canada for our scanning solutions and controls for the log bucking line and primary…We chose Porter because we believe they are the best value. When you power their equipment up, it’s ready to go to work and they have excellent service. Having the right scanning and controls can significantly improve the efficiency of your operation and allows for smarter processing.”

Boards are sent to the edger or resaw. Side cants go to the curve canter and gang. Cone-Omega also supplied its curve canter and curve sawing gang system, which ties into the outfeed of the sharp chain to accept the center cant and side cants.

This approach allows EWP to process larger than normal logs because it produces side cants. Edwards, declared, “We designed a lot of versatility into the new sawmill. It cost extra money up front, but I believe it will prove beneficial in the long run.”

This new mill primarily processes six-inch and eight-inch-thick center cants, which work well for internal pallet production and lumber headed to outside markets.

Cants are singulated and loaded into an infeed system, scanned by a Baxley cant optimizer and then placed on the optimized feed table. Then cants go through a curve canter and are swept off onto another deck. Cants are sawn in a Cone-Omega curve sawing gang designed with shifting pockets that can transition from 3.5 inches to 12 inches.

Boards that need to be edged, move to a Cone-Omega high-speed edger featuring Baxley optimization and controls. All lumber products then head to the Piché trim sort line, designed to handle a wide variety of material from 1x3s to large cants. The bin sorter can handle a wide variety of products. It is fully automated, which saves labor.

Edwards commented, “This was our first experience doing business with Piché, and it went very well. Our deal with them was turnkey so they installed all of their equipment, which included a line shaft trimmer, 50 bay sorter, two grading stations and the electrical and controls to run their entire line…They were the only vendor we used that did their own installation. They did a great job and were ahead of schedule throughout the project.”

Piché also supplied a fully automatic cant trimmer that feeds into two gang lines. This equipment automatically repositions to accommodate changes in dimensions eliminating downtime caused by manual adjustments. Edwards said, “I really like the way they designed the throughput chains in the trimmer. Their double acting tipples on the sorter are neat too and provide for a higher lug per minute operation to get the piece count we need.”

Edwards added, “The pallet trimmer features seven saws that move and set by the push of a button to desired length for fast changeover. We are feeding two gang saws behind this trimmer, and they designed a really innovative dispatch system to keep both gangs fed.”

Machine Built, Quality Focus

The first 20 years of Edwards’ operations centered solely around pallets, but in the late ‘80s, the company began producing grade lumber, then added kilns in the early ‘90s. Today, pallets make up about 35% of sales, with grade lumber making up another 35%, and the balance in industrial lumber products and by-products.

EWP currently has 15 Viking nailing lines, a combination of Turbos and rebuilt Duo-matics. Most of its pallets are produced on a nailing machine, but Edwards does build some specialty pallets. The company has worked with Pallet Machinery Group to upgrade older Viking machines with newer control. This upgrade improves operator efficiency and has allowed EWP to extend the life of its existing nailing fleet.

“The nailer upgrade programs that Greg Wine’s company provides are really beneficial to maintaining pallet production levels and keeping new technology on older machines,” explained Edwards. “Greg also provided eight new lumber stackers for the resawing portion of our new mill. They do a great job.”

Edwards added, “Well, we’ve had Viking forever. They are reliable, and we know how to get strong production out of Viking nailers. I don’t see us doing anything else when it comes to making stringer pallets.”

Focusing on quality, EWP uses NexGen mold treatment on a good portion of its pallet stock, and the company also dries a large percentage of its pallet stock. EWP relies on SII Dry Kilns due to their reliability and capacity.

“On our kilns, we started using SII on the first kilns we purchased in the early ‘90s and have used them ever since,” stated Edwards. EWP purchased a new natural gas direct fired batch kiln for the new mill. EWP chose natural gas because it requires less capital expenditure on equipment, is readily available, provides a more consistent flow to the burner compared to sawdust and has become cost effective due to expanded U.S. production.

SII has become a preferred supplier for EWP. Edwards explained, “I like the fact that SII will work with you to help you arrive at what you need from an equipment and control standpoint, so you have the ability to match equipment and design with your needs. We bought Batch kilns, but SII designed the kilns so we could go with the continuous flow upgrade at a later date. I like their fan design. They really move a big volume of air. That, combined with the correct burner size, really takes the moisture content down very quickly.”

Edwards Lumber Philosophy

Besides the size and scale of its operation, two things that set EWP apart are its wood procurement program and lumber manufacturing processes. The Marshville location includes a grade hardwood sawmill as well as pallet manufacturing, lumber drying and pallet lumber processing. The Laurinburg facility features the hybrid mill, some pallet manufacturing and drying capacity.

Edwards commented, “We take five species at the Marshville and Liberty sawmills– red oak, white oak, maple, poplar and ash. Everything else on the saw log portion goes into the production of cross ties, switch ties and industrial timbers – gum, hickory, elm, hackberry, sycamore, whatever, what we call the miscellaneous species. Some of this is processed at our new plant and some at our existing sawmill in Peachland, North Carolina.”

Edwards added, “We have diverted some of our gum and other soft hardwoods into the new hybrid mill because we can cut about 35,000 feet per hour there compared to 16-18,000 feet per hour at the Peachland plant.”

Edwards described EWP’s approach at the two chip mill facilities. He said, “We take tree length or double bunk hardwood pulpwood. Our system is designed where we can pull out better quality stems that then travel through an adjacent scragg mill operation to make pallet stock and the rest of the wood flows into a chipper to provide chips for paper companies.”

EWP generally receives 10-inch and larger saw logs that are two sides clear at the grade sawmills. Anything that is not two sides clear and is still desired is sent to the scragg operation. Incoming loads are weighed and then sorted in the log staging yard by species.

Besides its raw material philosophy, EWP runs every day based on key values. These are more than just mottos occasionally said by a company leader; these are principles guiding daily operations. See the Sidebar, “Core Values,” for more information.

Where is EWP headed in the future? The company continues to grow with a focus on continuous improvement in safety and operations. Edwards projected, “We are still focused on growth in the right place and in the right way.”

Edwards Wood Products Core Values

EWP focuses on eight core values. Jeff Edwards, president and CEO of EWP, said that he wakes up every day trying to lead his company to do its best to live up to its values and create a positive culture.

The company’s #1 value is safety with the objective to create, foster and maintain a work environment that is safe for all employees. Closely connected to that value is focus on people to always recruit, train and strive to retain the best talent. Edwards realizes that his company will only be as strong as his people and strives for an environment that makes people want to be a part of EWP’s organization.

Another core value that is hard to miss is equipment. Edwards stated, “We have and will continue to invest in the highest quality equipment and the most innovative technology available to our industry. We must maintain this equipment and the scanning and controls used in our processes to ensure it is performing at peak capacity.”

The next core value is cleanliness which relates closely to maintaining good working equipment and keeping workers safe. Equipment is only as good as its operators. EWP strives to have smooth and efficient operations with minimal downtime and disruptions.

The last three values focus squarely on the customer experience. Edwards explained, “We do what we say and follow through and honor your commitments.” Finally, EWP strives to be the best and beat the competition. These values are all easier said than done. But the success of EWP over the last 50 years speaks for itself.