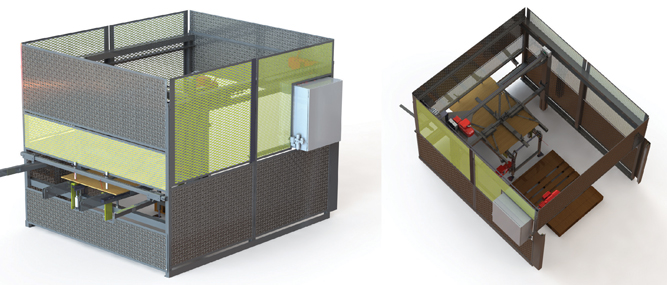

Recognizing the need for a compact stacker designed to boost handling efficiencies, Automated Industrial Technologies (www.autoindtech.com) has developed the ES50. The ES50 is a compact machine, with a footprint of 12’L x 8.5’W x 7.5’H, and is ideal for small lots, specialty materials and components, from 32" to 72" long. It stacks up to four layers per minute. Live demos of the ES50 Stacker are planned for the VFPA Expo Richmond event, (Richmond Virginia Raceway), October 9-10, 2020.

“Eighty percent of sawmills or pallet manufacturers have 20 or fewer employees. The E-Series stacker is intended for these small shops or for re-manufacturers who want to manage costs, grow their business, without having to add people, explained Chip Lamb, chief operating officer for AIT. “The ES50 installs easily, runs easily, and requires minimal supervision by the operator.”

Unlike some other equipment on the market, you don’t have to wait a long time to receive the new ES50. Lead time from order to delivery for the ES50 is estimated to be four weeks. Units will ship beginning in the 3rd quarter of 2020. The ES50 stacker is just part of a new E-Series of machines being designed by AIT for small shops and specialty product lines in the pallet industry.

Over the last 25 years, AIT has created a strong reputation for its stacker designs, especially the M2L and TS300 stacker systems that are known for speed, simplicity, and just getting the job done right.

As part of a processing station with a saw, chamfer, or notcher, the ES50 board stacker can accept materials directly on its infeed to stack with or without tie strips. Board stacks can be moved via forklift or manual pallet jack. Change-overs for different size boards are not complicated or time-consuming; all can be completed by the operator with two or three manual bolt adjustments to the infeed and the gantry and pick up arms.

The ES50 eliminates the need for a second operator to manage the output of a pop-up saw or upline process. Less manual handling speeds throughput and minimizes worker fatigue and injury risks due to bending or twisting.

“The labor savings alone is enough to justify the investment in this stacker,” explained Lamb. “At a base price around $35,000, it’s feasible to see a payoff in about one year.”

See this machine run now by viewing the ES50 demo video at https://youtu.be/9CYRFPr0h2I; the operator achieves labor savings with minimal handling of window sash components.

Do you want to know how this stacker will do with your boards? AIT now offers a testing service so you can eliminate any guesswork. Using customers’ own materials, AIT tests each machine and fine tunes its operation prior to shipping. Customers can view this run-off testing remotely and in real-time with an innovation exclusive to AIT called AutomationVueSM.

AutomationVue gives E-Series customers access to a secured video camera system in the build area of the AIT plant to see the ergonomics and operation of their ES50 stacker. In this way, operators learn the basic operation of the stacker via video in advance of installation. Plant managers avoid the expense of travel and time out of their plant to observe how ES50 handles the varied materials and changeovers planned in their operation.

“Simple, uncomplicated, and reliable is our main idea in designing and manufacturing all our machines,” stated Lamb. “Our E-Series machines have proven to optimize the number of boards that are processed per labor hour for the small shop or the low-volume operation.”

For more information on the ES50, visit www.autoindtech.com or call 434-525-2292.