The forest products industry has a promising future with the rise in development of cellulose nanomaterial and its many potential applications, according to a U.S. Forest Service researcher.

World Nieh heads the agency’s efforts to help develop new products and increase the utilization of wood fiber. He gave a presentation on ‘Bioeconomy – An Exciting Future for Forest Products,’ at the annual meeting of the Western Pallet Association in January.

Cellulose nanomaterial, or — think microscopic — cellulose, which may be in the form of fibers, a crystalline substance, or even bacteria. (A nanometer is one billionth of a meter, which is just over a yard; nanotechnology is devoted to materials in the 1-10 nanometer range.) Cellulose nanofiber, for example, is a gel-like substance that is thick under normal conditions but becomes more liquefied when shaken or agitated.

Cellulose nanomaterial is generating “a lot of excitement right now,” said World.

Products made with cellulose nanomaterials will be commercially available in the U.S within five years, he predicted. Some products already are available in Europe.

Applications include the food and beverage industry, personal care and household products, industry, paper making, oil drilling, oral care, and pharmaceuticals. Nanocellulose can be used in the manufacture of animal feed, agricultural products, batteries, carbon black, ceramics, textiles, coatings, flavors and fragrances, bioplastics, adhesives, emulsions, binders, water filters, and other products.

One application is concrete: cellulose nanomaterial adds strength to concrete. “It’s definitely an enhancement to concrete,” said World, and could be used to develop stronger concrete products and building products that require less concrete.

Products that potentially can be produced with cellulose nanomaterial include electrospun fibers, super-thin latex, batteries that can be folded, flexible viewing screens for electronic devices, water filters, ultra-thin loudspeakers, and more. Japan already has commercialized a couple of products that use cellulose nanomaterial — a writing ink that will not skip and adult diapers.

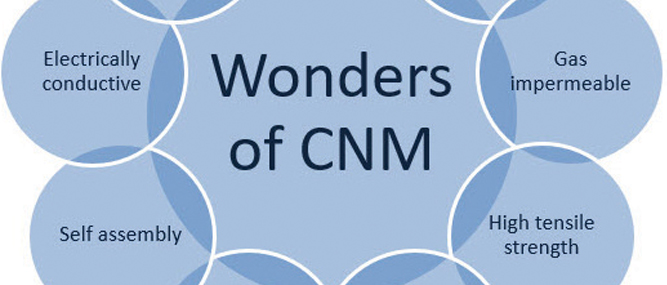

Cellulose nanomaterial is nontoxic, transparent, has high tensile strength (World compared it to Kevlar, which is used in bullet-proof vests), is electrically conductive, renewable, and has other attractive properties.

Just as smart phones have transformed the way of life for so many people, cellulose nanomaterial has the potential to create transformational technologies, said World. It is a “bright future for the forest products industry,” he said.

In response to questions from the audience, World noted that the paper industry already has the infrastructure — pulping technology — to produce cellulose nanomaterial. The only restriction is the economic viability of bringing the material to market.

The raw material likely would be in the form of wood chips although residual wood material potentially could be tapped in the future, he said.