From electrical shock to fires, electrical hazards must be a major consideration in your safety program. Last month we covered how electrical cords can lead to unsafe workplace conditions. And this second article on electrical safety looks at other key components from service panels and fuses to electrical motors, outlets and more. Learn how you can prevent electrocution and other problems resulting from faulty electrical practices.

Service Panels

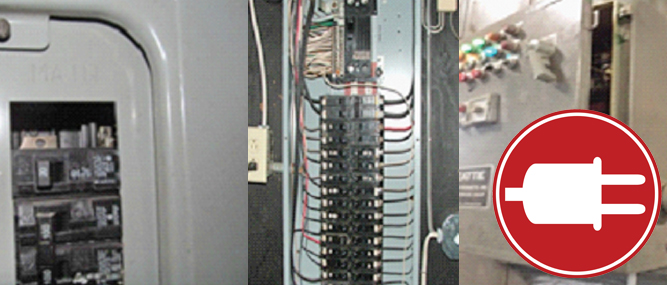

Service panels are often a source for an electrocution hazard. Electricians may remove and not reinstall the panel around the breakers, thus exposing personnel to an electrocution hazard. (See figure 1) When breakers are removed, assure that covers are placed where the breaker was removed. This prevents a person from accidentally placing their hand into the absent breaker position, and coming in contact with the bus bar. (See figure 2) Service panels, as well as power disconnects, must always remain accessible. Maintain clearances of 36" deep by 24" wide in front of these electrical controls. All circuits must be properly labeled for identification.

Electric Motors, Control Panels, and Switches

Another common electrocution source is switch covers, and electrical covers on motors. These are quite often removed for service, but not reinstalled. Control panel doors left open is another electrocution hazard. (See figure 3) Either of these situations is a failure to comply with the Control of Hazardous Energy Standard or Lockout – Tagout Program. These are both an electrocution hazard, and a fire hazard when combustible dusts or vapors are present. Assure all covers are reinstalled, and access doors are closed immediately after service work is performed.

Electrical Outlets, Junction Boxes, and Switch Covers

All electrical outlets, junction boxes, and switch covers must be in place, and undamaged. In my experience this is one of the most common violations cited by the Occupational Safety & Health Administration (OSHA), and certainly one of the most frequent OSHA Standard violations that I find. Cracked, damaged, or missing covers and faceplates must be replaced to reduce electrocution hazards.

Surge Protectors versus Multi-Plug Adapters

Surge protectors are a safe alternative to multi-plug adapters. Multi-plug adapters are almost always overloaded. Surge protectors protect valuable circuitry, computers, and electronics. Surge protectors are not considered extension cords, and therefore can be used long term. Surge protectors are required for computer workstations. The most common violation to standards that I see is daisy chaining surge protectors, or plugging one surge protector into another, connecting surge protectors to extension cords, and unsecured surge protectors hanging on a wall or a piece of machinery. A surge protector cannot be supported by its cord, it needs to be secured to protect the cord from stress.

Electrocution Hazards Equal Expensive Citations

When an electrocution hazard is found, it is quite often considered a Serious Violation, and these incidents carry the stiffest penalties. The OSHA compliance officer may even find it serious enough to stop production, until the hazard has been removed. This is a best outcome compared to an employee losing their life. I can think of numerous examples of electricians, millwrights, and other workers being electrocuted to death, just because safe practices were not followed.

Editor’s Note: Jary Winstead is a safety consultant, author and trainer who serves a variety of industries including the forest products sector. He owns Work Safety Services LLC and can be reached at SAFEJARY@aol.com.